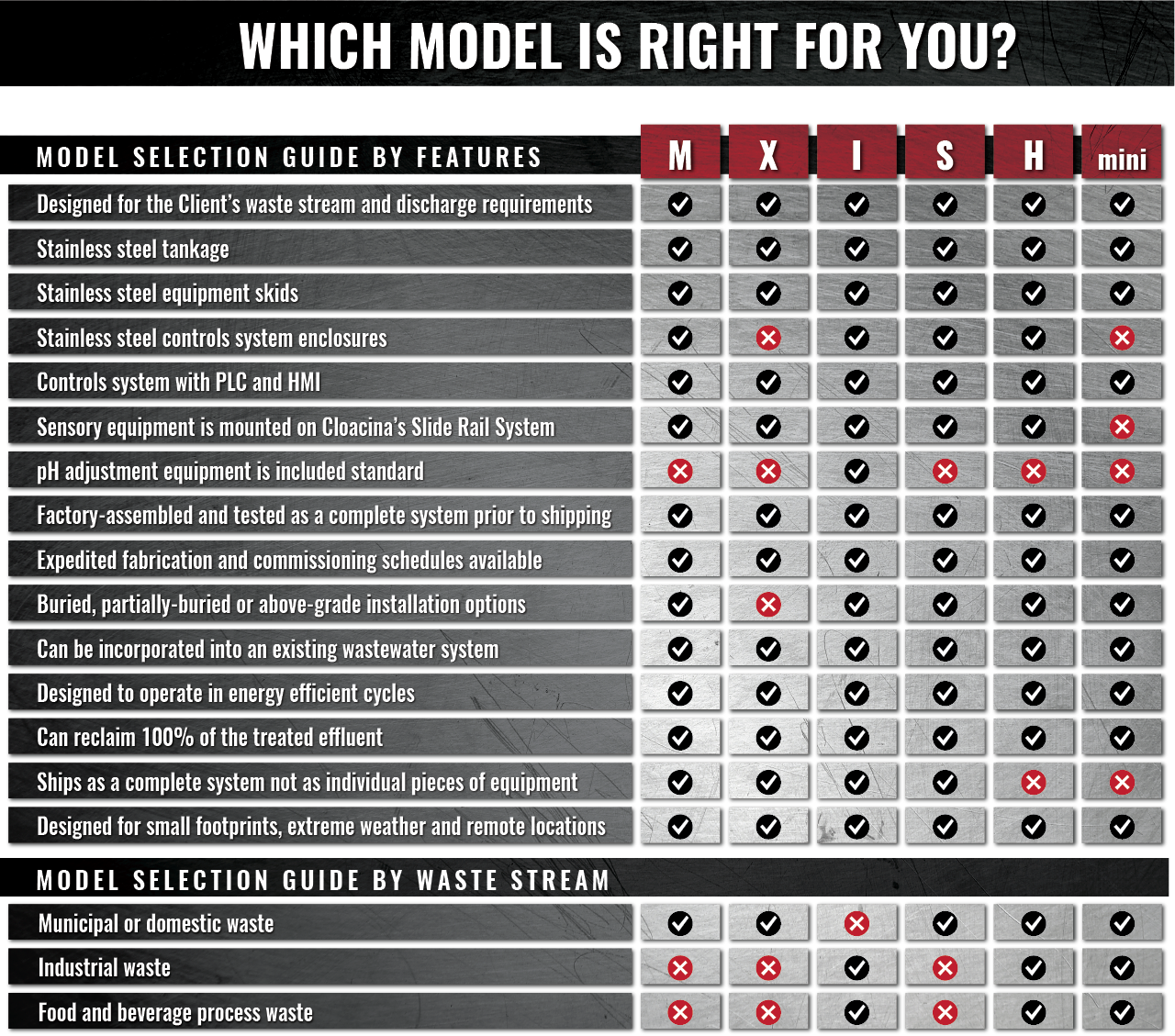

MEMPAC-M

Designed specifically to meet strict municipal project specifications, the MEMPAC-M is Cloacina’s unrivaled membrane bioreactor with the longest life cycle of any of Cloacina’s package wastewater treatment plants. The MEMPAC-M is designed for municipal clients with stringent discharge requirements or the desire to reclaim treated effluent for reuse or ground disposal.

The MEMPAC-M incorporates primary treatment, activated sludge and membrane clarification as the final stage of treatment. Unlike activated sludge wastewater plants that utilize a traditional clarifier, membrane treatment does not allow solids to carry over into the effluent.

This is the only MEMPAC model that comes standard with Cloacina’s premium equipment package. The MEMPAC-M typically features additional redundancy within the membrane system and ancillary equipment as well as biological or process modeling reports. All tankage and equipment skids are fabricated from stainless steel and all interior and exterior components are manufactured from high-quality, corrosion-resistant materials. Prior to shipment, all components are factory-installed and wet tested as a complete system. The compact design of the MEMPAC-M makes it ideal for projects with small footprints and remote locations.

Cloacina’s MEMPAC-M is the industry’s only membrane bioreactor that utilizes Forward Activated Sludge (FAS) to provide the motive force to keep the membrane interface at the proper viscosity and the maximum dynamic loading of the reactor volumes while maintaining the ideal Biological Nutrient Removal (BNR).

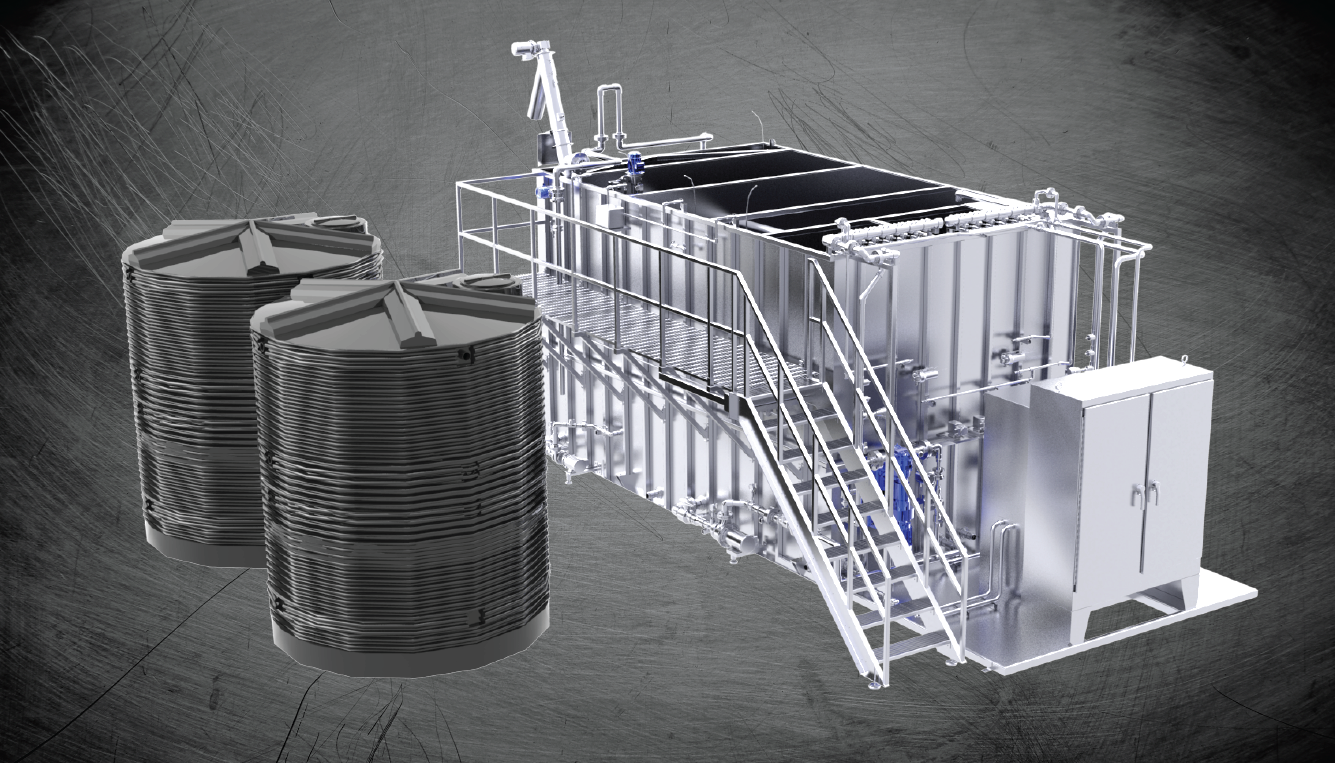

MEMPAC-X

Cloacina’s MEMPAC-X is a cost-effective treatment solution designed for low flow domestic applications with stringent discharge requirements. The base unit can treat up to 20,000 gallons per day and is designed to be easily expanded to treat up to 45,000 gallons per day with the incorporation of additional Cloacina or Client-supplied external tanks. This system can reclaim 100% of the treated effluent for irrigation and sanitation purposes and has expedited construction and delivery timelines.

MEMPAC-S

Cloacina’s MEMPAC-S (Scalping) is one of the most revolutionary products currently available in wastewater treatment. Untreated domestic wastewater is intercepted, pumped out of the gravity sewer into the MEMPAC-S, treated to reuse standards and then discharged to irrigate parks and common areas, used to offset agricultural, irrigation or commercial water usage or recharge groundwater supplies using direct injection. Untreated solids are returned to the sewer. A scalping plant is an alternative to centralized wastewater treatment that can provide secondary or tertiary treatment within a smaller facility.

In times of drought and mandatory water conservation measures, it is no longer responsible to irrigate sports complexes, flowerbeds and medians with potable water, nor is it tenable to continue to send a valuable resource to final discharge locations such as the ocean when communities are struggling to maintain groundwater balance. Fabricated from stainless steel, the MEMPAC-S can reclaim 100% of the treated effluent in accordance with Title 22 requirements or any other state or national regulations, lessening the strain on diminishing potable water and groundwater supplies. By performing treatment adjacent to the disposal location, a scalping plant is an affordable reuse option.

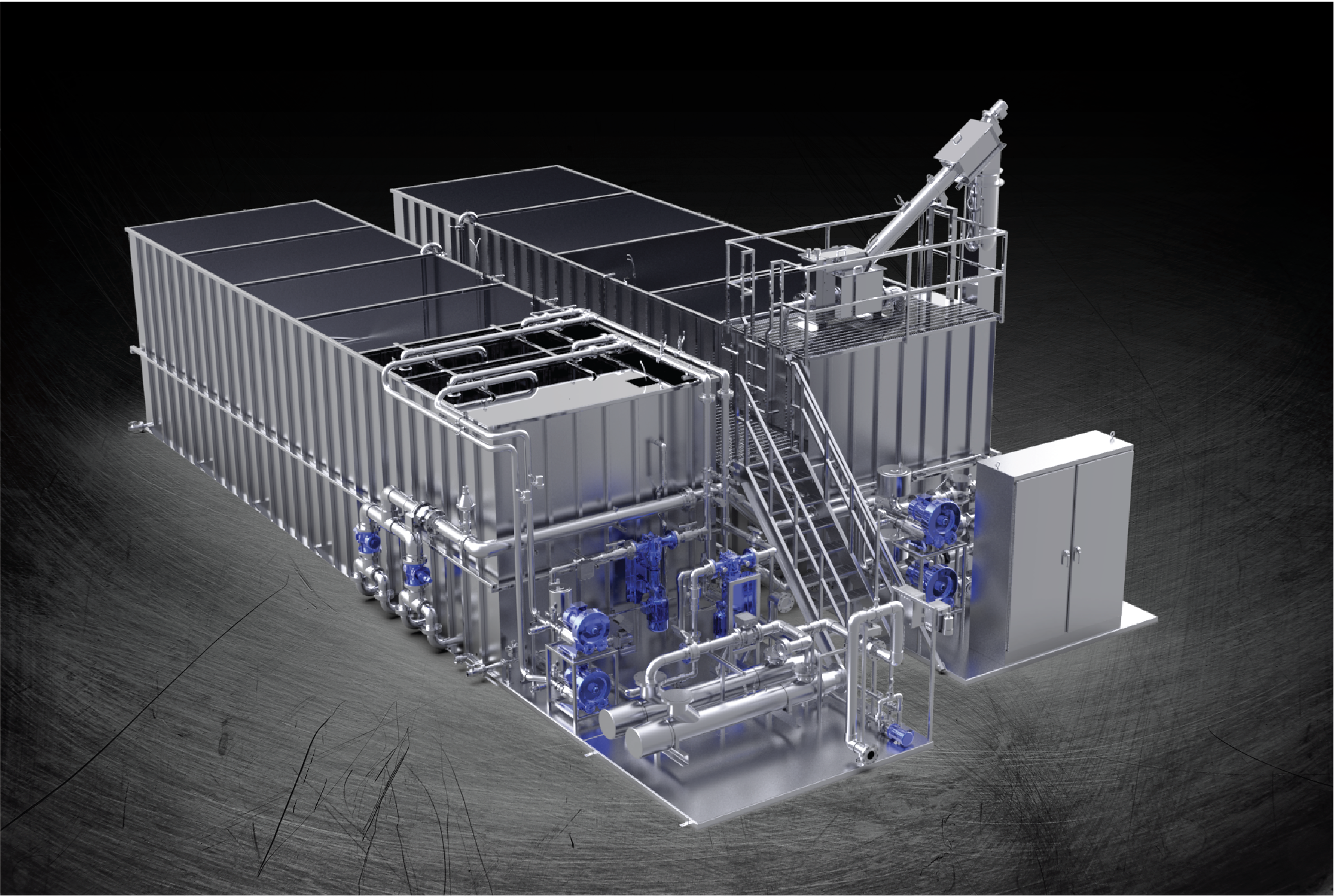

MEMPAC-I

The MEMPAC-I is a multi-process system designed to handle extreme loading, solids and high-strength waste from industrial clients including wineries, breweries and other food and beverage manufacturers. The MEMPAC-I includes the screening, primary treatment, activated sludge and membrane clarification necessary to stabilize fluctuating influent strength and loading while improving downstream treatment and performance. Unlike activated sludge plants that utilize a traditional clarifier, membrane treatment does not allow solids to carry over into the effluent. Every MEMPAC-I is custom engineered for the client’s specific waste stream, discharge requirements and their beneficial reuse or Direct Industrial Reuse needs.

MEMPAC-H

The MEMPAC-H is a hybrid equipment supply package designed for both municipal and industrial clients that need wastewater treatment equipment, but either already have or intend to supply their own tankage and piping. The MEMPAC-H is designed to accommodate extremely large projects and foreign clients that wish to minimize overseas shipping costs. This MEMPAC model uses Ultra Filtration (UF) membrane clarification and can either be a stand-alone unit or a complete Membrane Bioreactor (MBR) treatment system. These systems have expedited fabrication and delivery times and reduced on-site installation costs.

MEMPAC-MINI

The MEMPAC-MINI is a compact membrane bioreactor (MBR) system designed for small-scale wastewater treatment and re-use applications. Equipped with advanced membrane clarification, aeration, and control systems, the MEMPAC-MINI integrates with new or existing process—such as septic tanks, wastewater holding tanks, or ponds—to deliver efficient biological treatment. With a typical footprint of less than forty square feet, this stainless steel system is factory-assembled and engineered to reclaim 100% of treated effluent for re-use, offering a reliable and space-saving solution for low-flow applications.