We are proud to share this heartwarming video that explains Cloacina’s unique connection to the Pacific Islands! Learn more about how our culture as a company has been forever changed by the many Samoan young men that have worked for us and why we have much love and respect for the Islands.

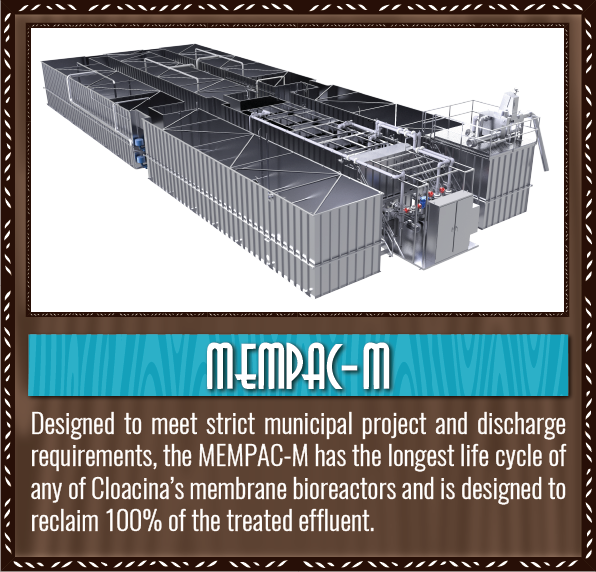

We are very proud to announce that a 150,000 gallon per day MEMPAC-M is coming soon to a resort on the Island of Kauai! Designed specifically to meet strict municipal project specifications, the MEMPAC-M is Cloacina’s unrivaled membrane bioreactor with the longest life cycle of any of Cloacina’s package wastewater treatment plants. The MEMPAC-M is designed for municipal clients with stringent discharge requirements or the desire to reclaim treated effluent for reuse or ground disposal. Stay tuned for more details about this exciting project!

Island conditions present a unique set of challenges for wastewater treatment projects. When considering installation or rehabilitation of wastewater systems, island-based clients, engineers, contractors and developers typically must consider the following:

Heightened public water quality and environmental protection agendas

Limited project budgets

The trend toward decreasing dependency on large municipal plants and shifting to smaller, local treatment solutions

Extreme weather conditions including high humidity, heavy rainfall and hurricanes

Accelerated rust and corrosion time frames that shorten the useful lives of materials and equipment

Remote site locations and steep on-site mechanical installation costs

High energy costs

Located less than five miles from the Pacific Ocean and in the heart of the Central Coast Wine Region, Cloacina faced many of the same challenges experienced on the islands when designing and fabricating wastewater treatment systems for West Coast clients: the most stringent discharge requirements in the United States, severe drought conditions and the need to reclaim treated effluent, corrosion due to ocean proximity and remote and heavily-foliaged project locations.

Cloacina’s Design Team spent years conceptualizing, building and testing a line of package wastewater treatment plants specifically for coastal, island and remotely-located clients.

Cloacina is proud to do our part to protect our water resources and the environment! Our MEMPAC models offer clients and the public many environmental benefits:

Reclaiming treated effluent for agricultural, irrigation and sanitation purposes

Aids in efficient water consumption

Can help decrease or prevent contamination of ground-water supplies

Helps support aquatic life by regulating nitrogen and nutrient levels in the water supply

MEMPACs occupy a much smaller footprint than other treatment systems

Automation and remote monitoring allows for easy operation which facilitates compliance even in remote locations

Ultrafiltration membranes can remove pathogens, bacteria and viruses

Reusing wastewater results in a lower water footprint for the client

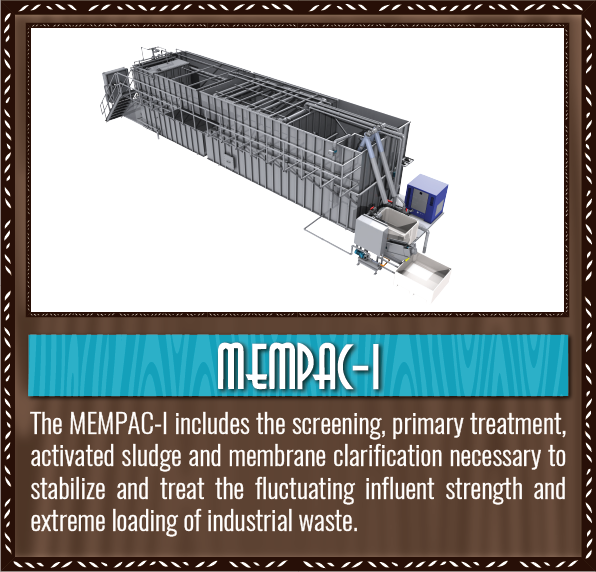

Cloacina’s line of MEMPAC™ Membrane Bioreactors (MBR) are revolutionizing package wastewater treatment. Designed for energy-conscious clients with stringent discharge requirements and the desire to reclaim treated effluent for irrigation or sanitation purposes, all MEMPACs integrate activated sludge and membrane clarification as the final stage of treatment. Every MEMPAC is fabricated from corrosion-resistant stainless steel, goes through rigorous factory acceptance testing prior to shipping, ships as a complete, factory-assembled system and can reclaim 100% of the treated effluent for irrigation and sanitation purposes. System and controls equipment are mounted on Cloacina’s Slide Rail System. All MEMPAC models can be installed in buried, partially-buried or above-ground orientations, can be designed to accommodate small footprints and are ideal for remote locations.