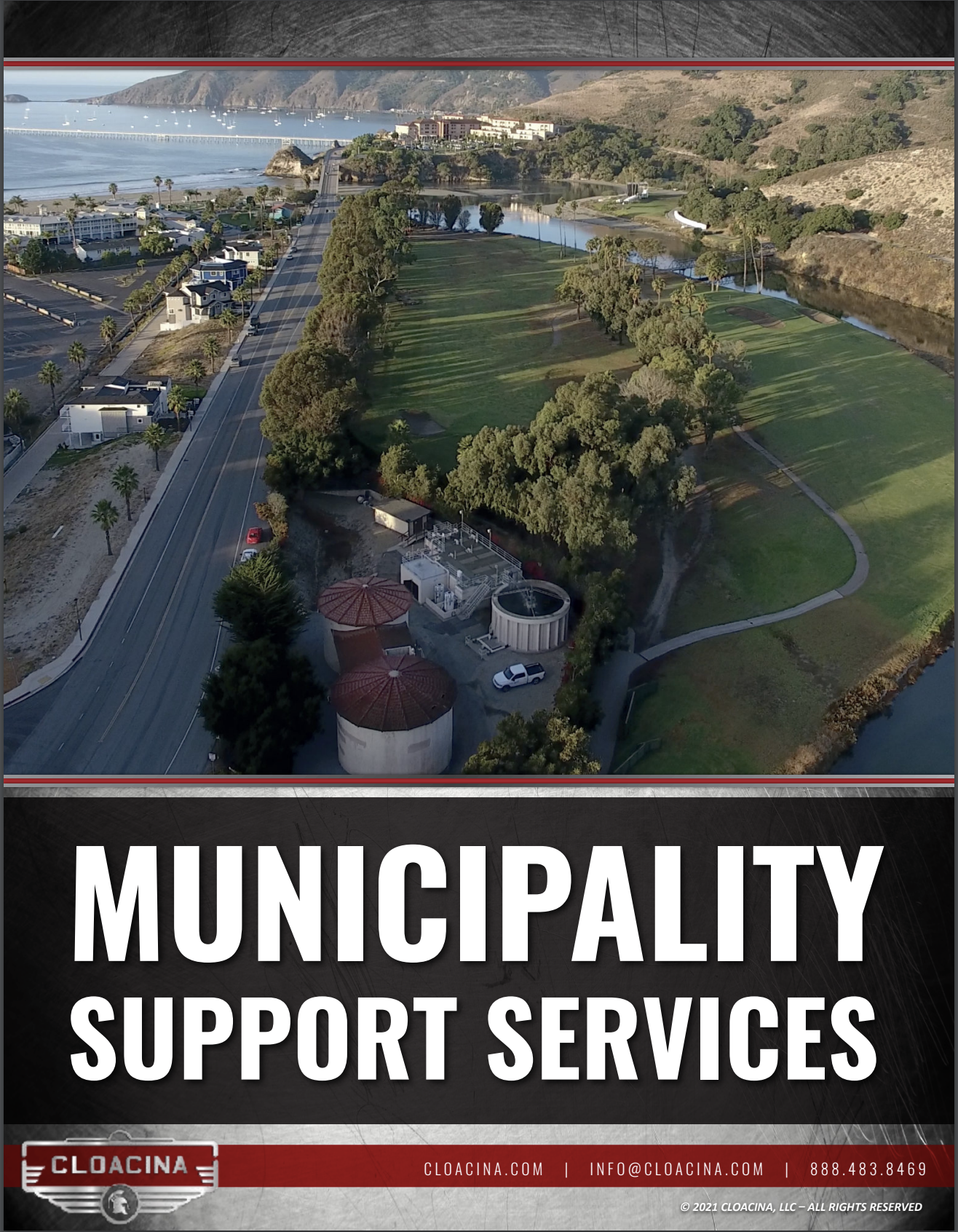

Traditionally, Municipalities have relied on outdated systems for wastewater treatment. Cloacina offers a modern alternative to conventional project methods, providing a more community-centric approach that empowers you to control costs. It's time for districts to have a say in their system's future.

PROVEN TECHNOLOGY - BUILT BY OPERATORS FOR OPERATORS

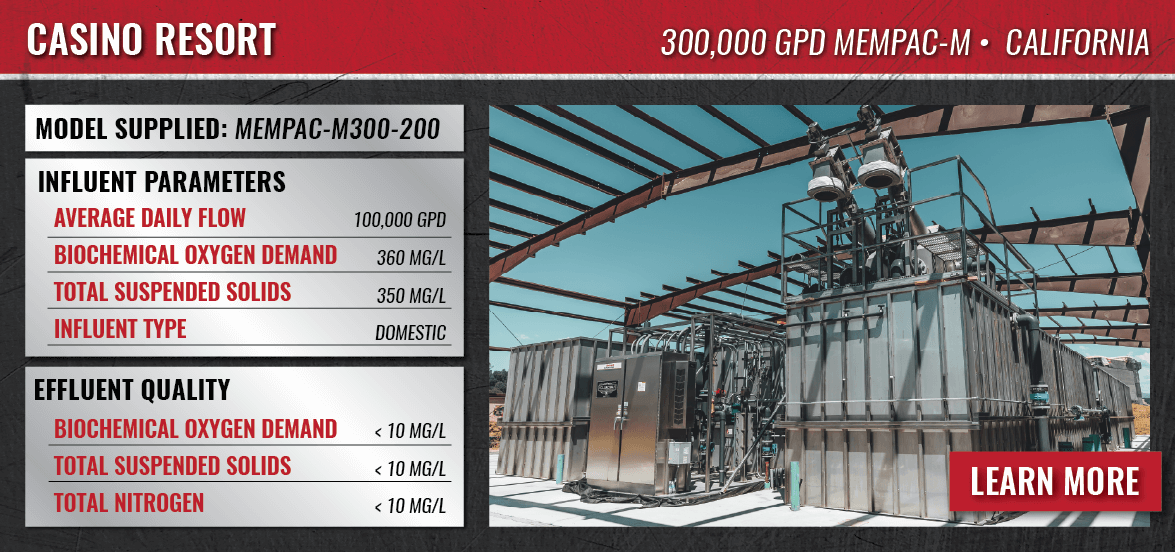

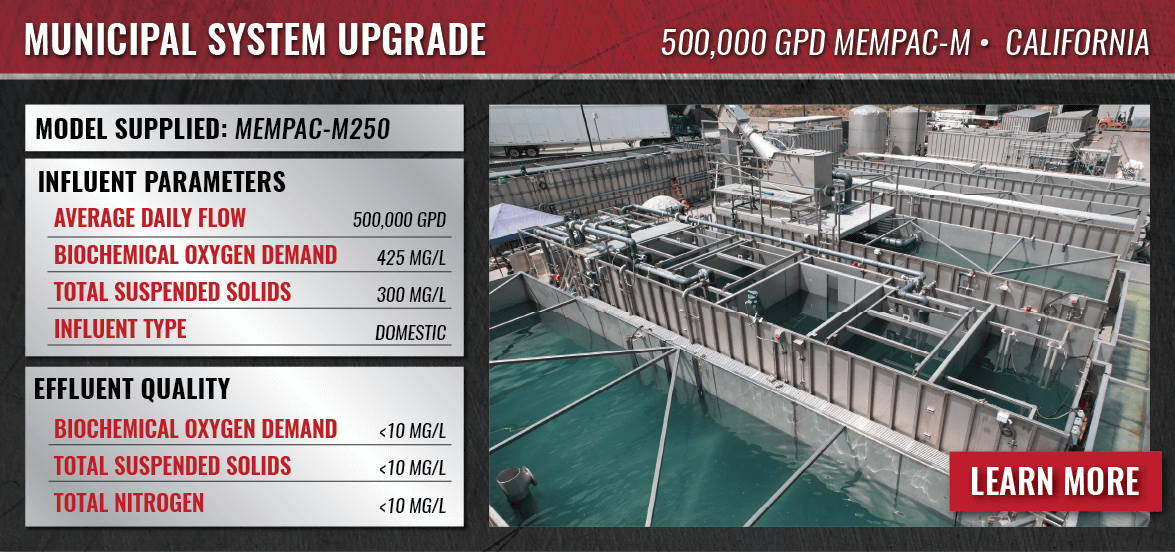

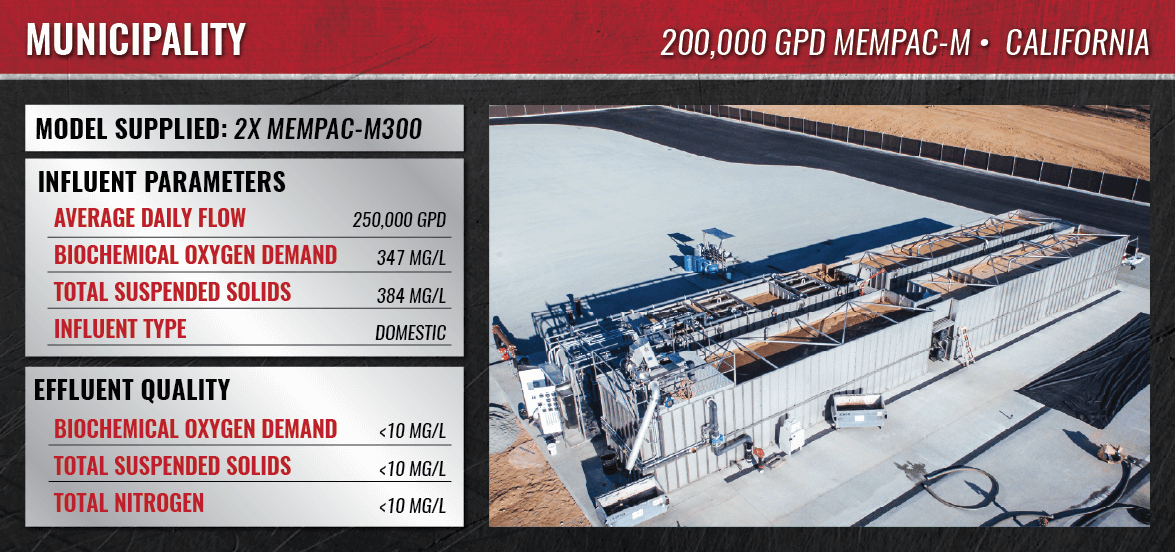

Cloacina's pre-engineered municipal systems match or exceed the quality and performance of custom-engineered sites. Leveraging scale, our systems are refined beyond what's achievable with traditional projects, shifting the focus from projects to product-oriented conversations.

Cloacina was founded by four municipal water and wastewater treatment chief plant operators, maintenance mechanics and construction superintendents. After decades working on a variety of systems, they decided to establish Cloacina and build package wastewater treatment plants and equipment. Their goal was to produce plants that make operations and maintenance tasks easy. Cloacina systems are designed by operators for operators.

Cost Effective and efficient

A fraction of the cost of traditional cast-in-place plants, Cloacina package wastewater treatment plants come pre-engineered for the client’s specific waste stream, discharge permit and project phasing.

Cities across the nation are embracing Cloacina’s pre-engineered approach for their municipal wastewater projects. By pre-engineering, prefabricating and pretesting equipment allows for the early detection and correction of non-conformities, reducing project time and costs.

Single point of contact and liability

Unlike the traditional multi-point contact approach that leads to communication issues and blame-shifting, Cloacina provides a single point of contact and liability. This ensures clear communication, decisive action, and effective solutions, with seamless accountability ready to serve your project for decades.

SERVICES TO SUPPORT YOUR MUNICIPALITIES PROJECT

Responsive team members that assist you every step of the project

Single point of liability with equipment supply

Master plan alternative analysis

Facility and phasing assessments

Short term rental units so discharge requirements can be met during construction

Tertiary, headworks and redundancy upgrades

Solids management

Sludge thickening and dewatering

Decentralized systems allowing for increased capacity in the central plant

Systems that reclaim 100% of the treated effluent for irrigation or sanitation purposes

WHAT IT'S LIKE TO WORK WITH CLOACINA

CLOACINA: INDUSTRY INNOVATORS

See why numerous engineers, project managers and winemakers choose Cloacina over other systems.

CLIENT INTERVIEW

Vera Rangel - Project Engineer

County of Los Angeles Internal Services Department

CLIENT INTERVIEW

Joe Hurliman - Winemaker

Herzog Wine Cellars

WHAT SETS OUR PRODUCTS APART

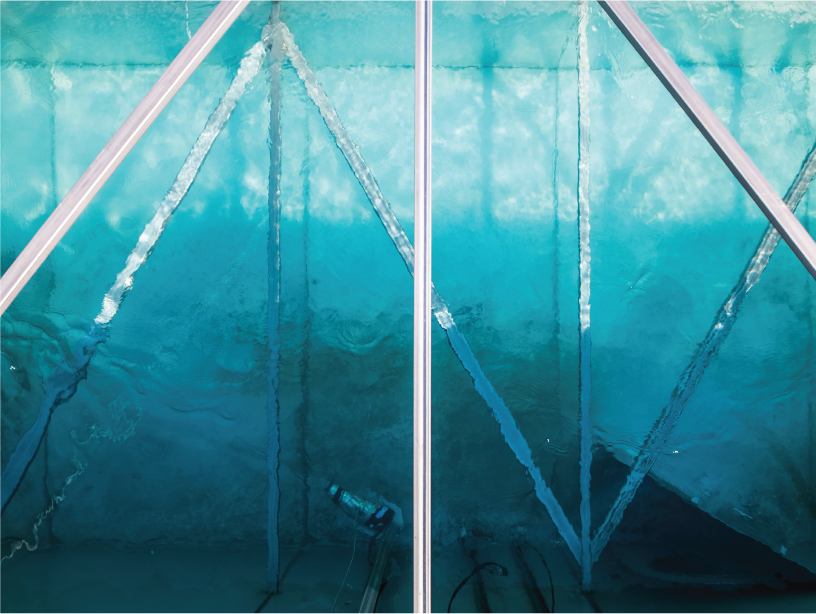

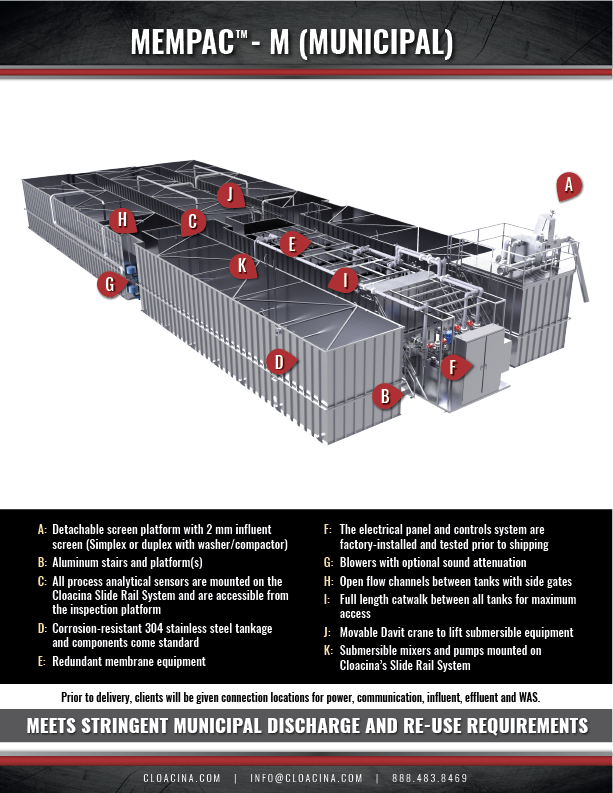

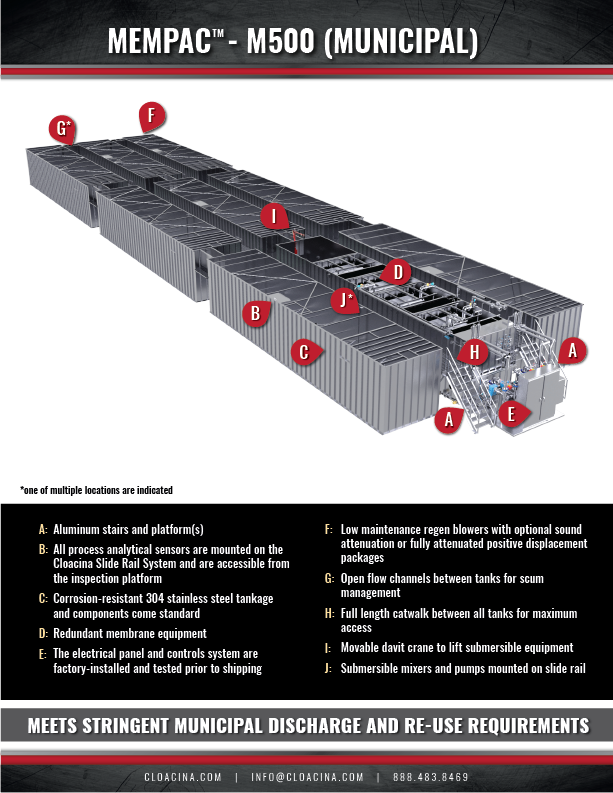

Stainless steel tankage and equipment skids come standard on all models

Our plants are designed to last decades rather than years

Every Cloacina wastewater treatment plant and piece of equipment undergoes rigorous Factory Acceptance Testing (FAT) of the plumbing, mechanical, electrical and controls systems prior to shipping

Models are available for installation in small footprints, remote locations and extreme weather

Plants ship as factory-assembled, complete systems not as individual pieces of equipment that have to be assembled for the first time on-site

Clients can reclaim 100% of the treated effluent for irrigation and sanitation purposes