Over the past decade, Cloacina has become a trusted resource for commercial and residential developers of both small and large-scale projects. Our Design Team specializes in helping Clients with stalled development plans find water and wastewater treatment solutions that will allow their projects to move forward.

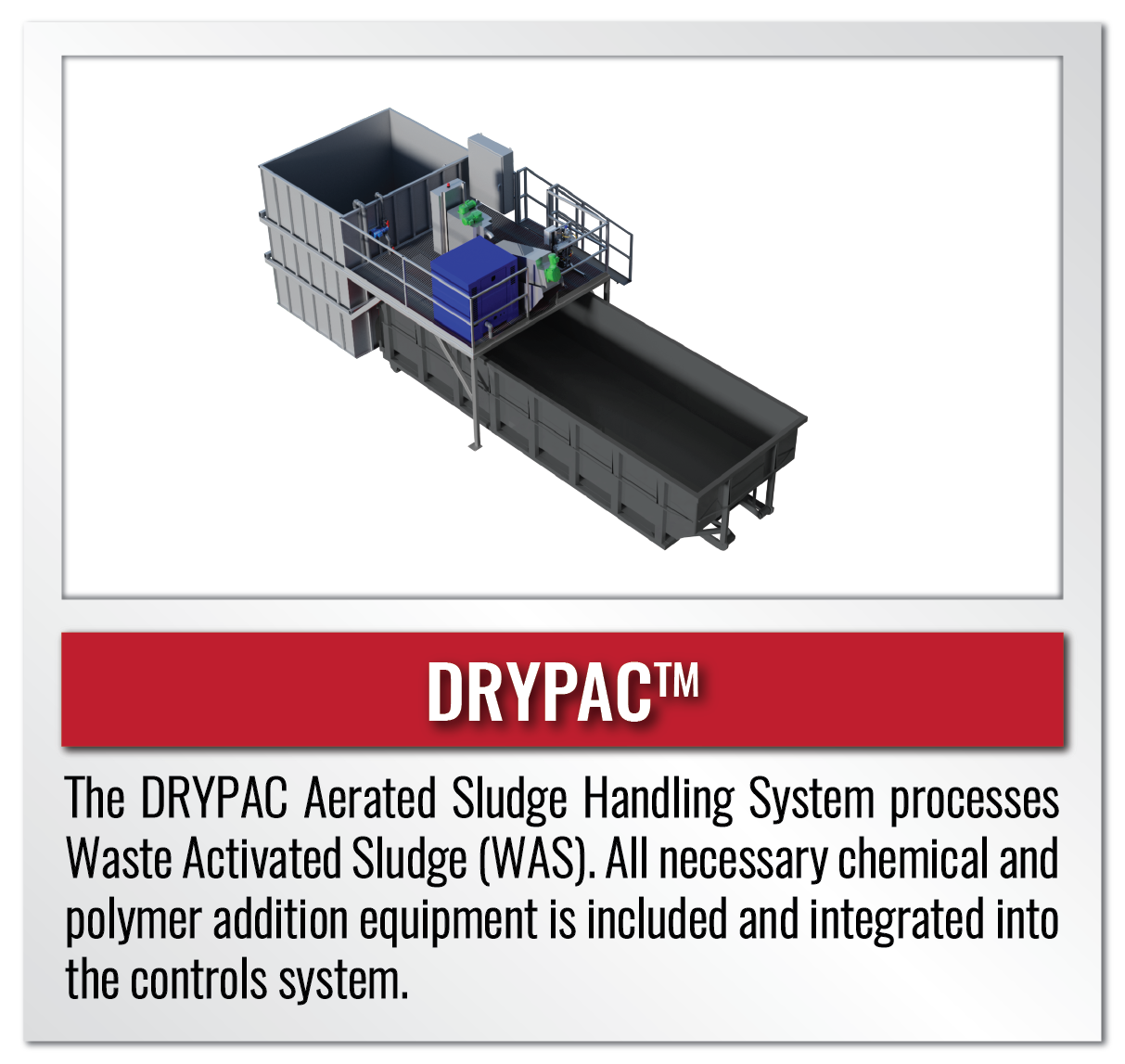

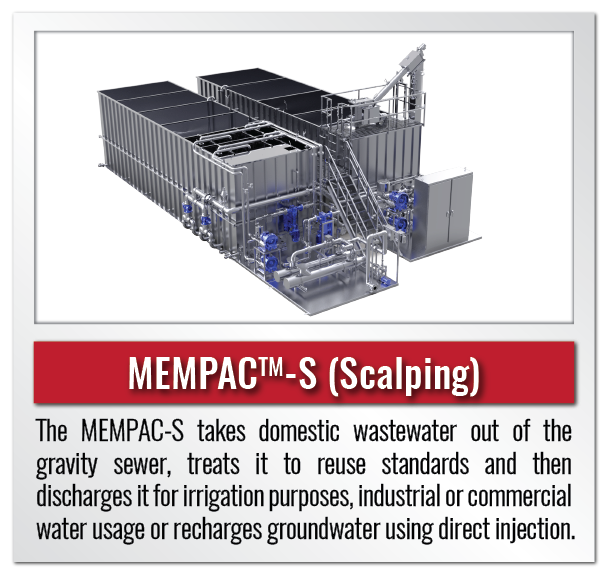

Cloacina manufactures package wastewater treatment plants designed specifically for developments that are capable of treating domestic or industrial wastewater or a combination of both. They are energy efficient, easily maintained, occupy small footprints and can reclaim 100% of the treated effluent for irrigation and sanitation purposes.

Developers often find that connecting their projects to downstream municipal treatment plants is expensive and that they can treat water on-site for costs equivalent to or less than connection fees and surcharges. On-site treatment turns treated effluent into an asset and commodity for the development.

Engineer/Manufacture/Build/Operate (EMBO) services

Cloacina can act as a liaison between the Client and regulatory agencies governing the project

Accurate project budgets for design and feasibility

Short and long-term rental plants

Lease and purchase options

Scalable products that can phase treatment system construction with the development

Expedited construction schedules

Water and wastewater consulting

Value engineering

CLOACINA: INDUSTRY INNOVATORS

See why numerous engineers, project managers and winemakers choose Cloacina over other systems.

CLIENT INTERVIEW

Vera Rangel - Project Engineer

County of Los Angeles Internal Services Department

CLIENT INTERVIEW

Joe Hurliman - Winemaker

Herzog Wine Cellars

“We recently successfully completed a highly complex job with Cloacina at the Tesoro Viejo Wastewater Treatment Plant. The packaged membrane bioreactor that Cloacina designed and provided is of excellent quality. I would like to reiterate the confidence that our company has established in Cloacina.”

Ruben Moreno, Jr

Senior Project Manager

W.M. Lyles Co.

Redundancy in wastewater design is a safeguard to ensure that treatment plants are capable of providing consistent, reliable and effective operation not only when the system is working correctly, but also in the event of unpredictable circumstances such as equipment failure, higher-than-anticipated flows or loading or natural disasters. Typical redundancy requirements ensure that wastewater systems can continue to process peak flows with the largest unit out of service and that the system can store influent peak flows to prevent spilling or discharging untreated effluent.