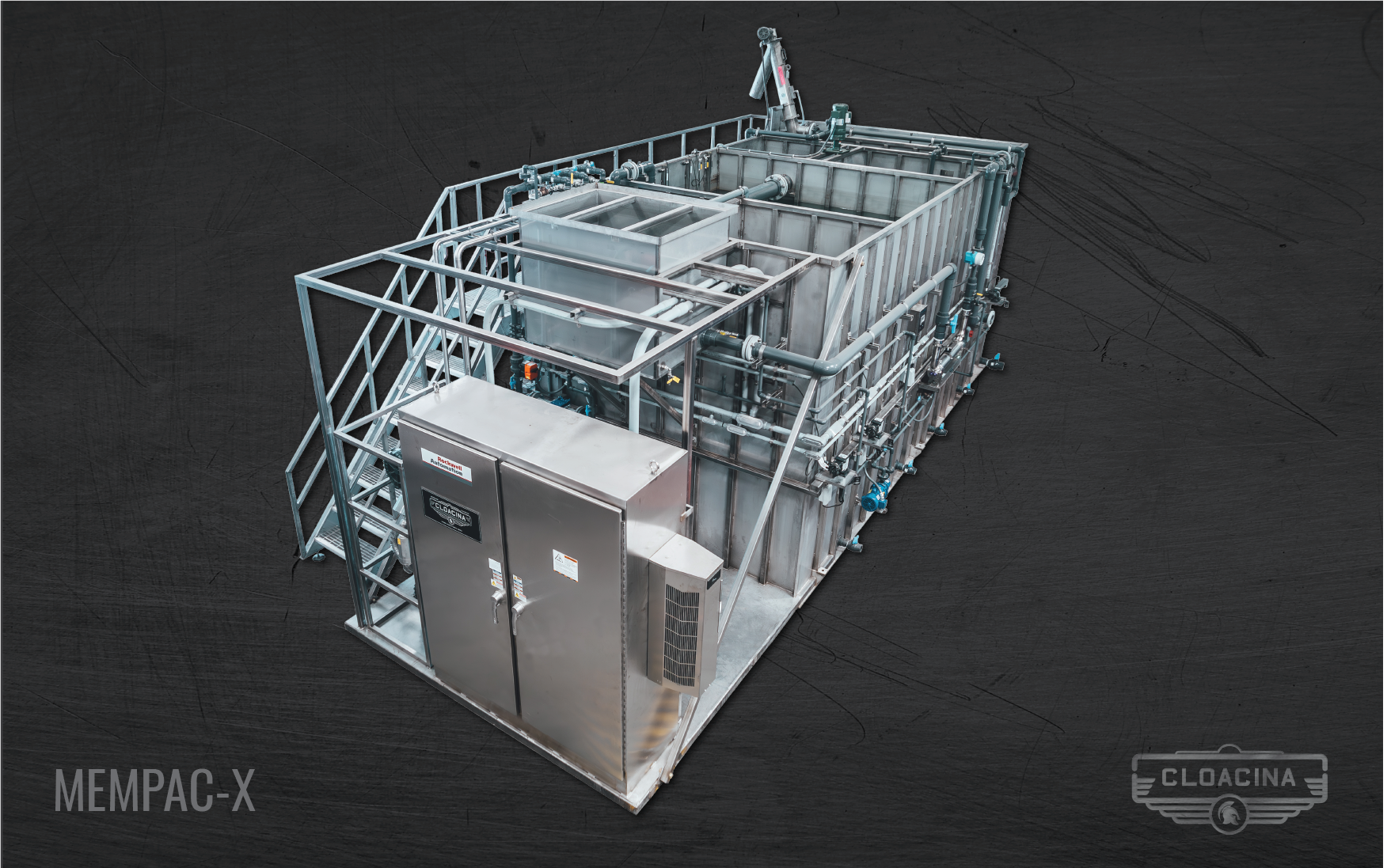

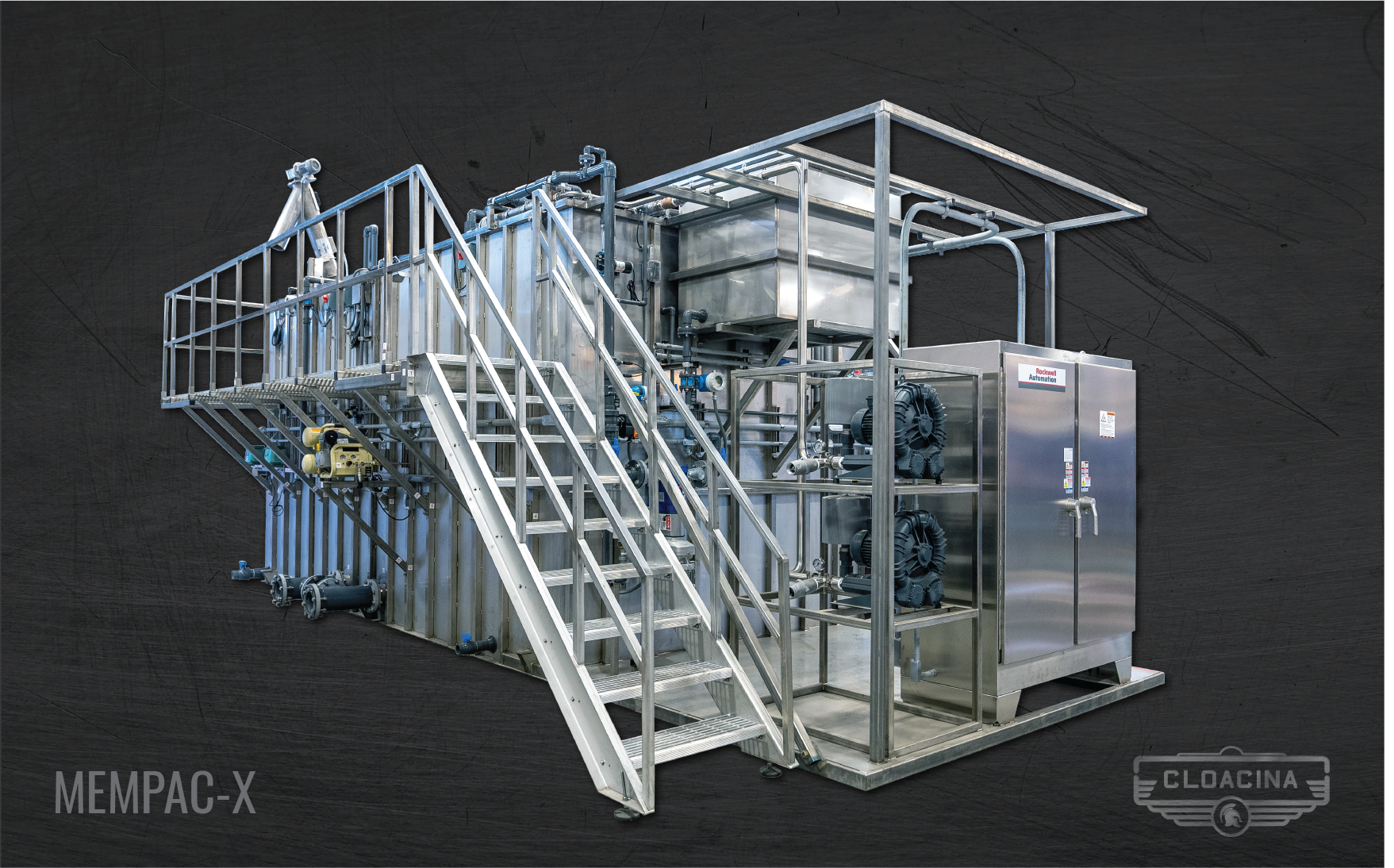

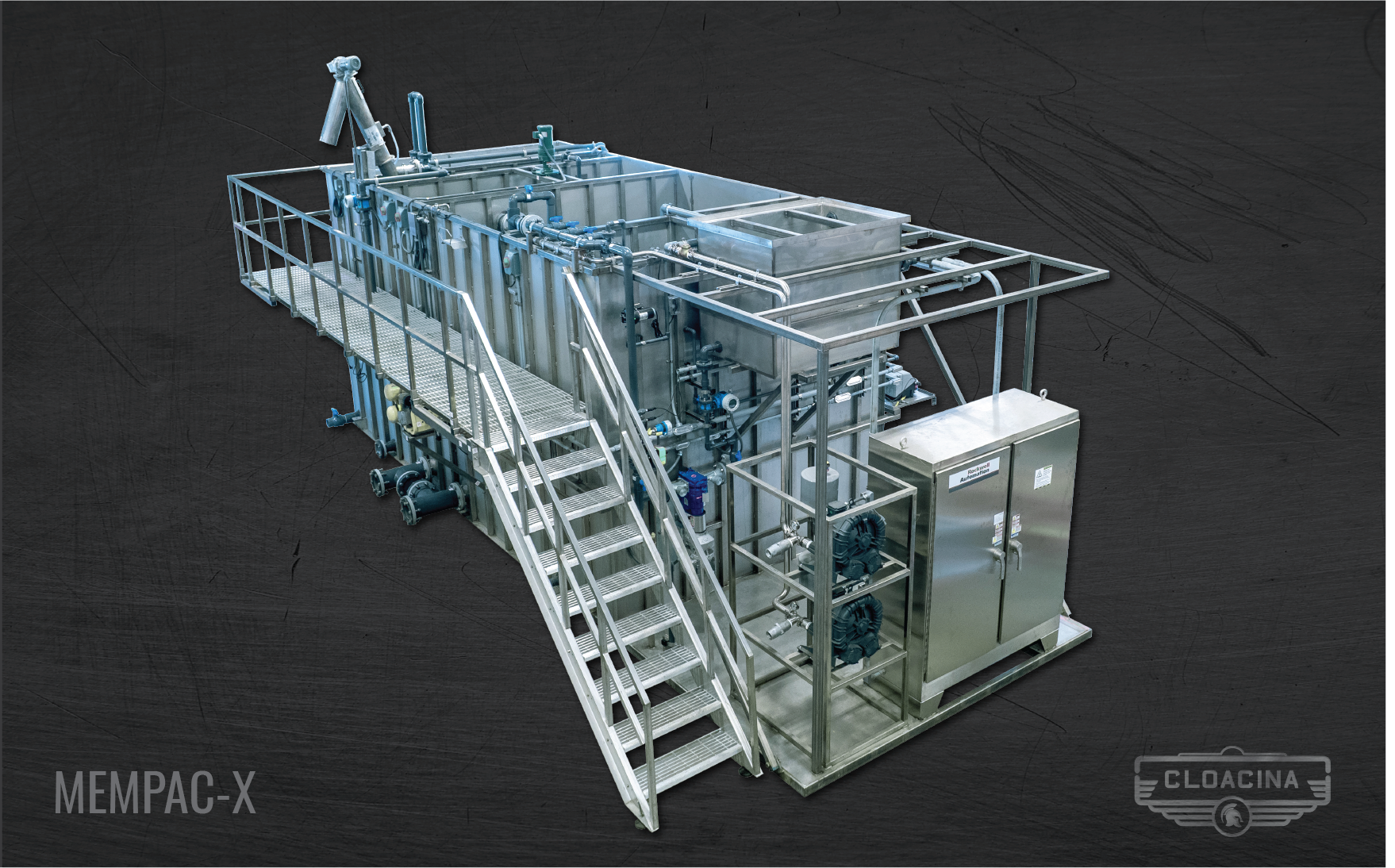

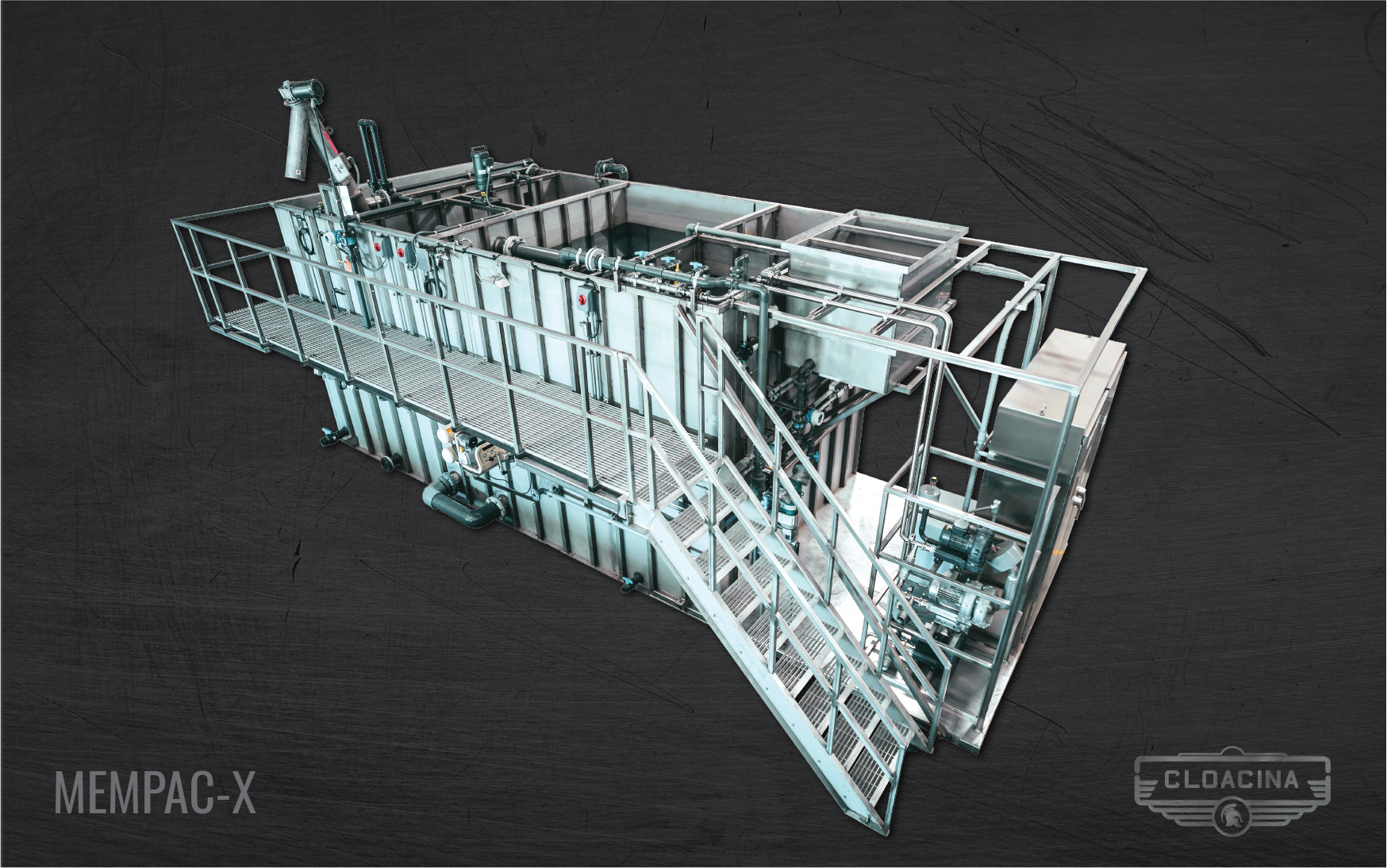

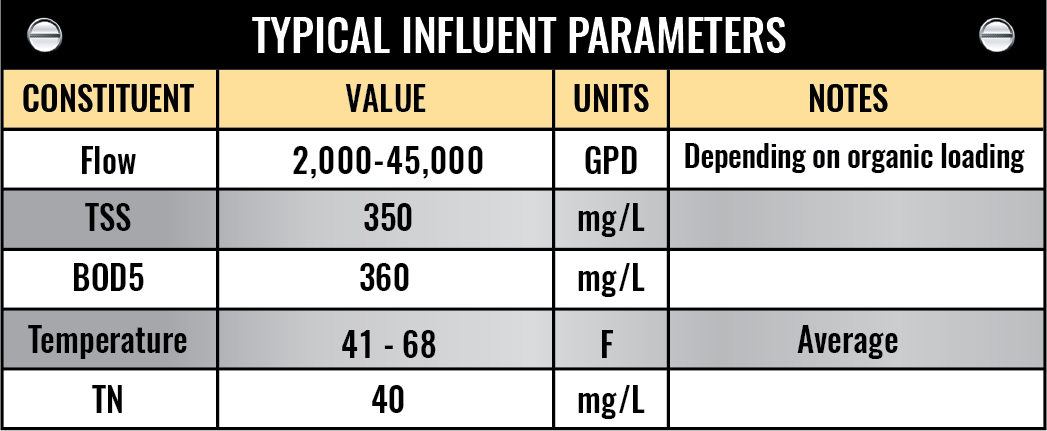

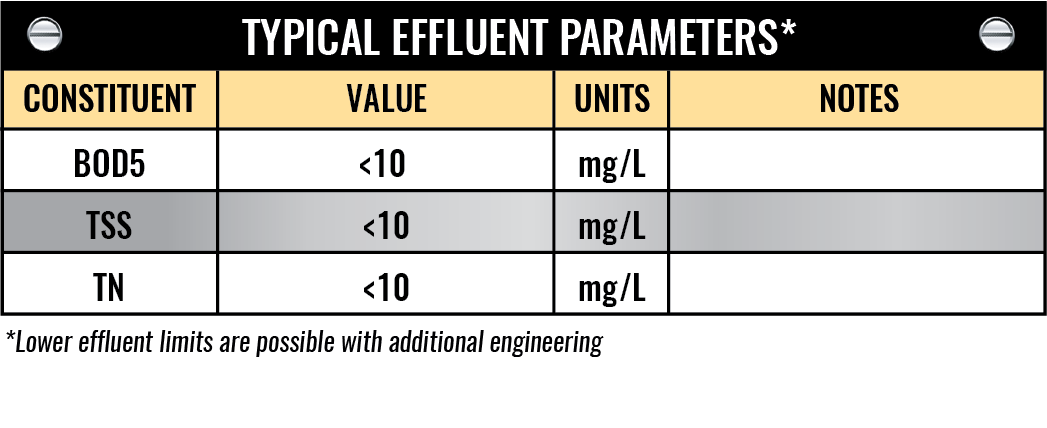

Cloacina’s MEMPAC-X is a cost-effective treatment solution designed for low flow domestic applications with stringent discharge requirements. The base unit can treat up to 20,000 gallons per day (average) and is designed to be easily expanded to treat up to 45,000 gallons per day with the incorporation of additional Cloacina or Client-supplied external tanks. This system can reclaim 100% of the treated effluent for irrigation and sanitation purposes and has expedited construction and delivery timelines. Download the MEMPAC-X Product Overview.

Typical Applications

The MEMPAC-X is designed for clients with seasonal or intermittent populations that substantially impact the day-to-day flow and loading but still have to meet stringent discharge requirements, including:

STANDARD FEATURES

304 stainless steel reactor tankage

Membrane cassette(s)

Modular medium bubble diffusers

NEMA 4X electrical panel

OPTIONAL FEATURES

pH adjustment system

Nutrient reduction

Package lift station

Sludge storage

Sound enclosures

Odor mitigation equipment

Automated foam control

Variety of grating and covers available

Installation oversight by factory trained technician

Operations and maintenance training and services

Remote monitoring and support

MEMPAC PRODUCT LINE

ABOUT CLOACINA

CLIENT INTERVIEWS