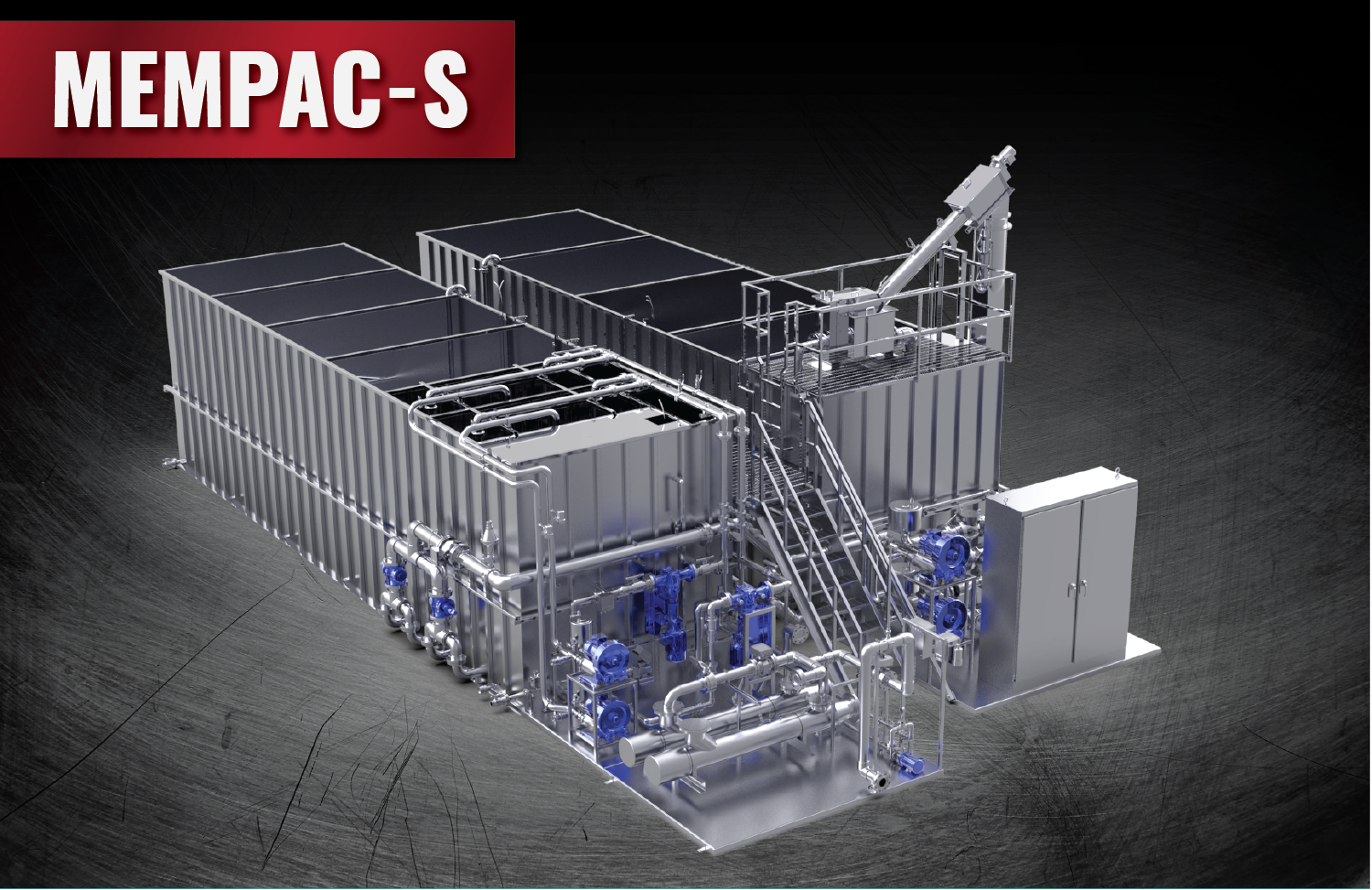

PRODUCT OVERVIEW

Cloacina’s MEMPAC-S (Scalping) is one of the most revolutionary products currently available in wastewater treatment. Untreated domestic wastewater is intercepted, pumped out of the gravity sewer into the MEMPAC-S, treated to reuse standards and then discharged to irrigate parks and common areas, used to offset agricultural, irrigation or commercial water usage or recharge groundwater supplies using direct injection. Untreated solids are returned to the sewer. A scalping plant is an alternative to centralized wastewater treatment that can provide secondary or tertiary treatment within a smaller facility.

In times of drought and mandatory water conservation measures, it is no longer responsible to irrigate sports complexes, flowerbeds and medians with potable water, nor is it tenable to continue to send a valuable resource to final discharge locations such as the ocean when communities are struggling to maintain groundwater balance. Fabricated from stainless steel, the MEMPAC-S can reclaim 100% of the treated effluent in accordance with Title 22 requirements or any other state or national regulations, lessening the strain on diminishing potable water and groundwater supplies. By performing treatment adjacent to the disposal location, a scalping plant is an affordable reuse option.

OPERATIONS AND MAINTENANCE-FRIENDLY FEATURES

Cloacina's package wastewater treatment plants are designed by operators for operators. Our Ownership Team has been building, installing, operating and maintaining water and wastewater systems for almost three decades. As a result, we know what operators and maintenance technicians need. Some of the revolutionary operations and maintenance-friendly features of our package wastewater treatment plants include:

Submerged sensory equipment is mounted on Cloacina’s Slide Rail System which provides mounting and support of equipment requiring precise installation and repeated removal for calibration and maintenance. This allows multiple pieces of equipment to be installed in tight spaces without tension on or tangling of power cords and controls cables.

The MEMPAC-S has built-in foam migration to keep foam and scum moving through the system and into a trap at the end of the treatment train

All process tankage on the MEMPAC-S has isolation gates for maintenance and emergency purposes

Equipment has pressure gauges or transducers for troubleshooting

All equipment has unions and/or flanged fittings for easy access and maintenance

All equipment is visible and easily accessed, maintained and replaced

We offer more sensory equipment and monitoring points on our systems than any other manufacturer

All models include self-cleaning probes

Our controls program provides:

Graphing

Trending

Charting

History

We provide built-in logic for oxygen control, nitrogen reduction and sludge management

STANDARD FEATURES

304 stainless steel tankage

Membrane cassette(s)

Aeration blowers

Modular medium bubble diffusers

Waste sludge return pump

All sensory equipment is mounted on Cloacina’s Slide Rail System

Above-grade installation

Human Machine Interface (HMI)

OPTIONAL FEATURES

Extended warranties

pH adjustment system

Advanced Biological Nutrient Removal (BNR)

Package lift station

Incorporation of existing controls equipment into Cloacina’s controls system

Effluent flow metering

Equipment sound attenuation

Thermal protection

Odor mitigation equipment

Automated foam control

Operations and maintenance training and services

Remote monitoring and support

Effluent Storage

Irrigation pumps and controls

TYPICAL APPLICATIONS

Cities, districts, golf courses, PPP (Private/Public/Partnerships), corporations desiring water credit offsets, groundwater recharging, agricultural offset or clients wishing to push off costly regional plant upgrades

WHAT IS A SCALPING PLANT

A scalping plant is a decentralized alternative to centralized wastewater treatment plant that can provide comparable treatment (Secondary or tertiary) within a smaller facility. The liquid portion of the raw wastewater mined from the sewer is treated and the solids are returned to the sewer. By performing treatment adjacent to the disposal location, a scalping plant is an affordable reuse option.

VIDEOS

MEMPAC PRODUCT LINE

ABOUT CLOACINA