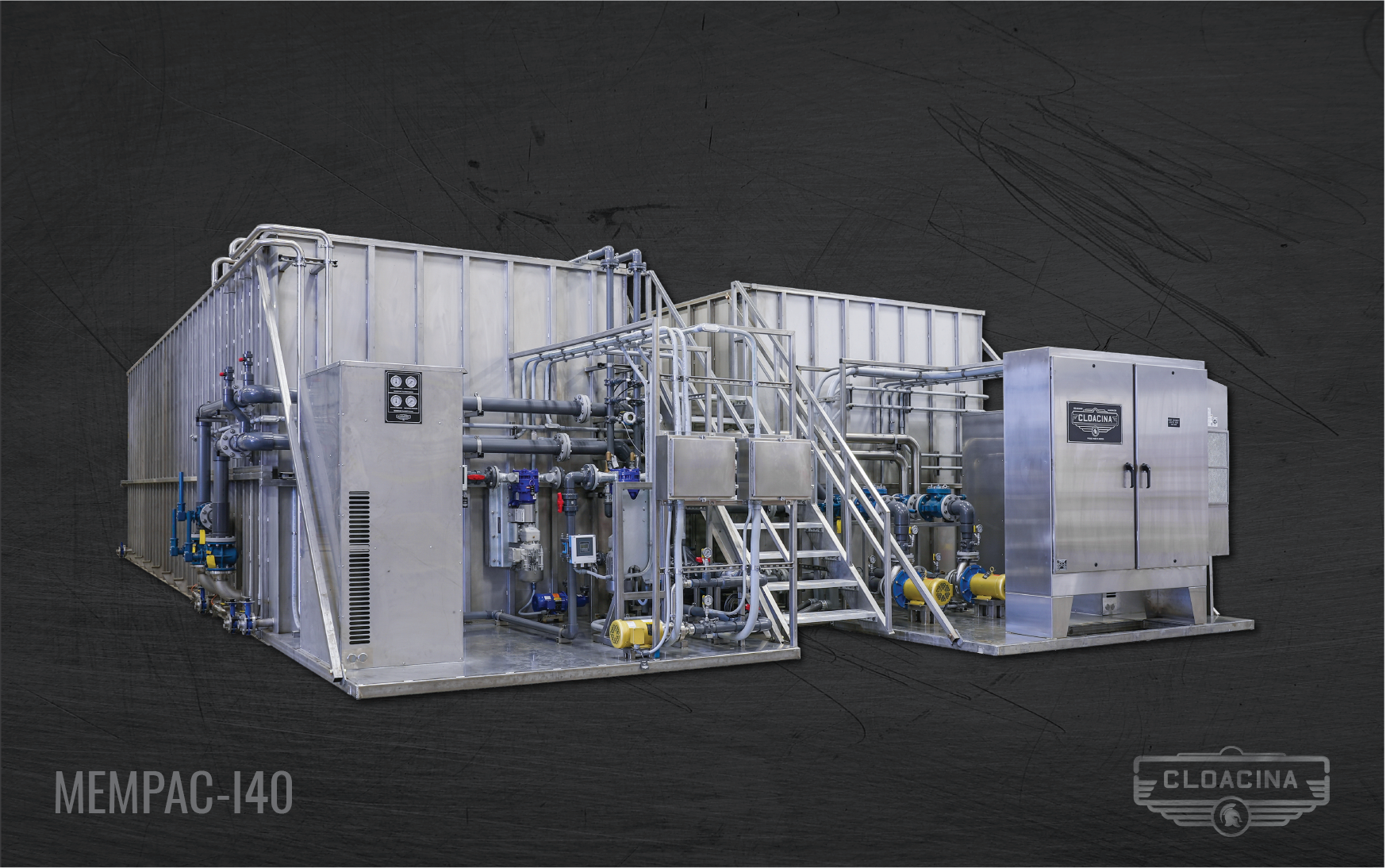

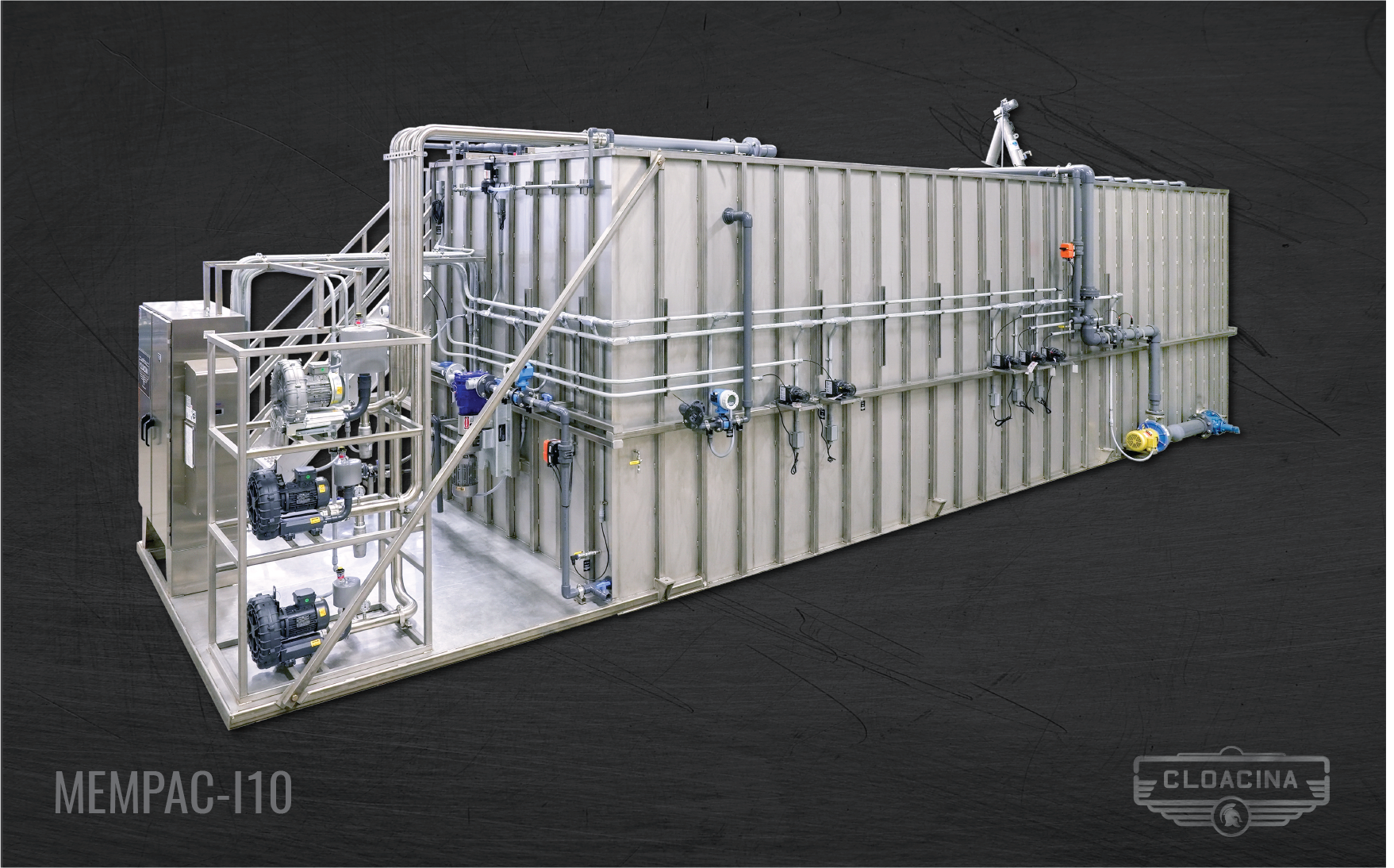

Cloacina’s MEMPAC™-I industrial membrane bioreactor is a package wastewater treatment system designed to treat high-strength process waste for clients with stringent discharge requirements or the desire to reclaim treated effluent for reuse.

The MEMPAC-I utilizes the Cloacina PRIMEPAC as a pre-treatment process prior to secondary treatment. The downstream equipment stabilizes fluctuating influent strengths and loading while improving downstream treatment and performance.

All interior and exterior components of the MEMPAC-I are manufactured from high-quality, corrosion-resistant materials and all tankage and equipment skids are fabricated from stainless steel. Prior to shipment, all components are factory-installed and wet tested.

The compact design of the MEMPAC-I makes it ideal for projects with small footprints and remote locations.

Typical Applications

The MEMPAC-I is designed for clients with high-strength, industrial process waste including:

STANDARD FEATURES

304 stainless steel tankage

Controls package

Membrane cassettes

Automated Clean In Place (CIP) system

All sensory equipment and internal pumps are mounted on Cloacina’s Slide Rail System

Above-ground installation

Human Machine Interface (HMI)

OPTIONAL FEATURES

pH adjustment system

Denitrification

Influent lift pump station

Sludge storage equipment

Sludge dewatering

Incorporation of existing controls equipment into Cloacina’s controls package

Effluent flow metering

Automated foam control

Extended warranty

Equipment sound attenuation

Thermal protection

Odor mitigation equipment

Operations and maintenance training and services

Remote monitoring and support

MEMPAC PRODUCT LINE

ABOUT CLOACINA

CLIENT INTERVIEWS