CLOACINA QUALITY. AT SCALE.

ABOUT THE MEMPAC-H

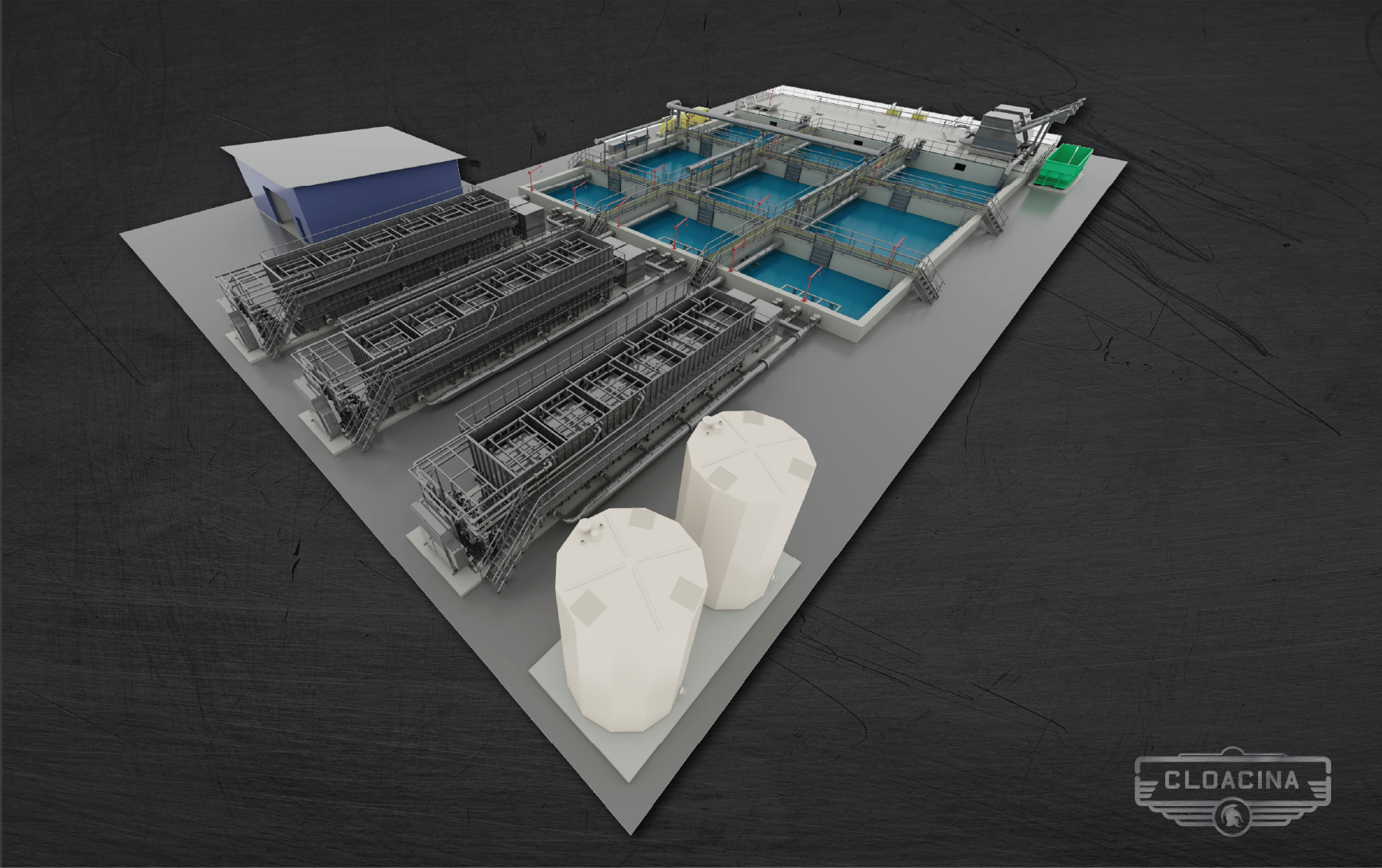

The MEMPAC-H is a pre-engineered membrane bioreactor (MBR) system that combines Cloacina’s packaged treatment expertise with the flexibility of cast-in-place infrastructure.

Designed for both municipal and industrial applications, the MEMPAC-H supports two distinct delivery paths:

GREENFIELD CONSTRUCTION For clients building new wastewater treatment infrastructure, MEMPAC-H offers a complete MBR solution using pre-engineered, modular cast-in-place bioreactor designs paired with prefabricated stainless steel membrane systems. This configuration provides the benefits of packaged treatment such as speed, performance, and operator accessibility, along with the scalability of civil-built infrastructure. This path supports projects in the 1–5 MGD range.

BROWNFIELD CONSTRUCTION For facilities that already have process tankage or plan to self-perform the civil scope, MEMPAC-H is also available as a membrane-only equipment package. This allows clients to expand capacity, improve effluent quality, or convert to MBR using existing infrastructure. This path supports projects in the 1–10 MGD range.

Each system uses ultrafiltration (UF) membranes for high-quality effluent and dependable performance. The design features modular, independent membrane trains that simplify cleaning, streamline operation, and support phased capacity increases.

Supporting multi-MGD flows, the MEMPAC-H delivers the same performance and reliability as the MEMPAC-M system, with faster lead times and reduced on-site installation costs.

It is the only pre-engineered hybrid MBR solution on the market, designed to accelerate project delivery without compromising process integrity.

STANDARD FEATURES

These are the core components and systems included with every MEMPAC-H model.

- Intuitive and advanced controls system

- Human Machine Interface (HMI)

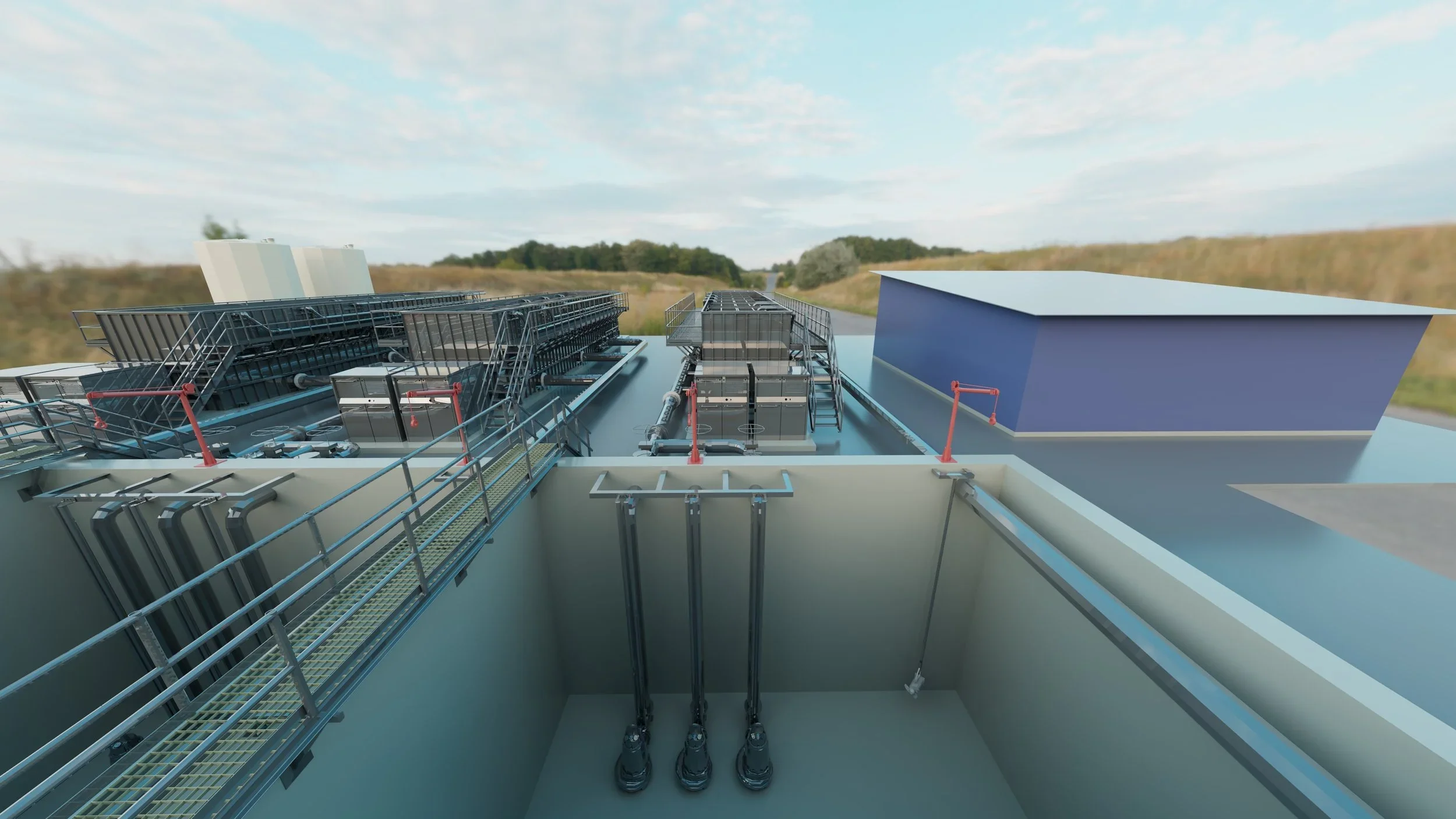

- All submersible mixers on slide rails

- Fine bubble aeration diffusers

- Low maintenance regenerative blowers

- Open-top flow channels between tanks with stop gates for isolation

- Independent membrane trains allow for maintenance or cleaning to be done without affecting capacity

- Automated Clean In Place (CIP) system

- Electrical panel and controls are factory installed on integrated equipment skid

- Corrosion-resistant 304 stainless steel tankage and components

- Aluminum stairs and platform(s)

- Catwalk supplied along the length of the system

- All process analytical sensors are mounted on the Cloacina Slide Rail System and accessible from the catwalk

- Davit crane and individual receivers for all submerged equipment

- Local disconnects and junction boxes for all motorized equipment

- Redundant membrane equipment

- Automated foam control

- Effluent flow metering

- Remote monitoring and support

- Factory tested prior to shipping

- Basic operations and maintenance training services

OPTIONAL FEATURES

Optional features are enhancements or upgrades that can be added to the base MEMPAC-H system to meet specific operational needs and are not factored into the base cost shown.

- Upgrade of stop gate to a weir gate for isolation

- Low-flow configuration and equipment

- Advanced treatment to meet lower nutrient limits

- Positive displacement blowers

- Sound-attenuated blowers

- Thermal protection

- Equipment awnings

- Extended warranty

OPTIONAL EQUIPMENT/SERVICES

Optional equipment refers to standalone products that can be seamlessly integrated with the MEMPAC-H system. Clients can select optional equipment based on site-specific needs and are not factored into the base cost shown.

- Effluent disposal pump station

- Centralized or integrated influent screening

- Sludge disposal equipment

- UV disinfection equipment

- Installation support

- Equalization storage and equipment

- Sediment and grit traps

- Package lift station

- Odor control equipment

- Operations and maintenance training video and portal support

COMPATIBLE PROCESS TANKAGE

MEMPAC-H compatible process equipment can be installed in cast-in-place concrete, fiberglass and bolted and welded steel tankage.

OPERATIONS AND MAINTENANCE-FRIENDLY FEATURES

Designed by operators, for operators. With nearly three decades of experience, Cloacina builds wastewater treatment plants that make operation and maintenance simple, safe, and efficient.

Operations & Maintenance-Friendly Features

EASY MAINTENANCE

Unions, flanged fittings, and visible layouts make equipment fast to access and replace.

SMARTER CONTROLS

Built-in graphing, trending, charting, and history tools simplify system monitoring.

CLEANER OPERATION

Foam migration, self-cleaning probes, and pressure gauges keep the system running smoothly.

OPERATOR FOCUSED DESIGN

More sensors and monitoring points than any competitor, designed for real-world use.

BUILT-IN LOGIC

Automated oxygen control, nitrogen reduction, and sludge management for efficiency.