TYPICAL APPLICATIONS

Remote domestic waste such as mobile home parks, resorts, schools, campgrounds, commercial developments, truck stops and rest areas.

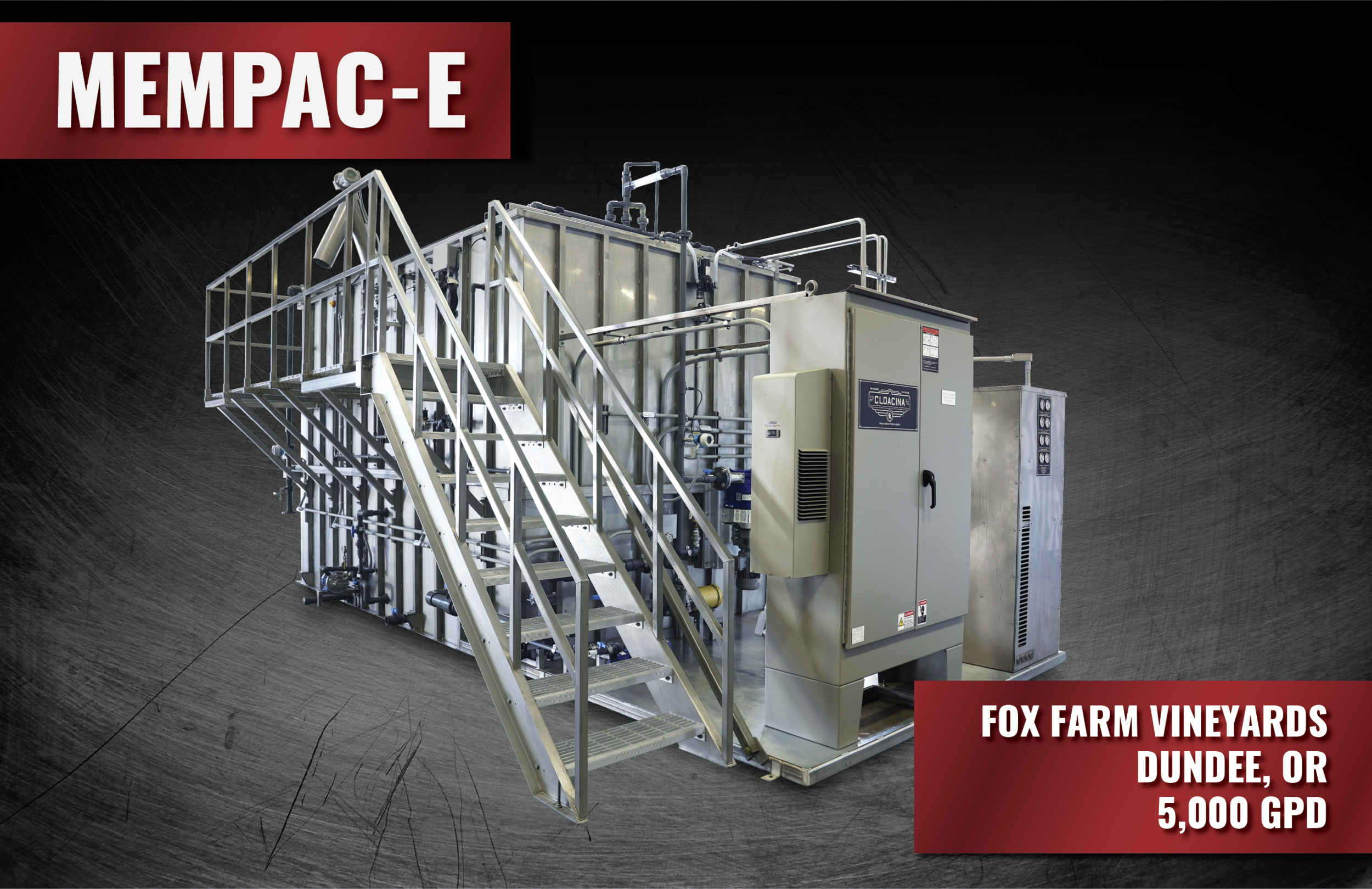

PRODUCT OVERVIEW

The MEMPAC-E membrane bioreactor is the perfect package wastewater treatment system for municipal clients who need an immediate treatment solution, those who are budget-conscious but still have to meet stringent discharge requirements or those with the desire to reclaim treated effluent for re-use. Designed for low flow ranges, the MEMPAC-E has standard, streamlined designs and economized equipment selections while still incorporating many of the same features that clients have become accustomed to on other MEMPAC™ models: all interior and exterior components are manufactured from high-quality, corrosion-resistant materials and all tankage and equipment skids are fabricated from stainless steel. Prior to shipment, all equipment is factory-installed and wet tested. The compact design of the MEMPAC-E makes it ideal for projects with small footprints and remote locations.

OPERATIONS AND MAINTENANCE-FRIENDLY FEATURES

Cloacina's package wastewater treatment plants are designed by operators for operators. Our Ownership Team has been building, installing, operating and maintaining water and wastewater systems for almost three decades. As a result, we know what operators and maintenance technicians need. Some of the revolutionary operations and maintenance-friendly features of our package wastewater treatment plants include:

Submerged sensory equipment is mounted on Cloacina’s Slide Rail System which provides mounting and support of equipment requiring precise installation and repeated removal for calibration and maintenance. This allows multiple pieces of equipment to be installed in tight spaces without tension on or tangling of power cords and controls cables.

The MEMPAC-M has built-in foam migration to keep foam and scum moving through the system and into a trap at the end of the treatment train

All process tankage on the MEMPAC-M has isolation gates for maintenance and emergency purposes

Equipment has pressure gauges or transducers for troubleshooting

All equipment has unions and/or flanged fittings for easy access and maintenance

All equipment is visible and easily accessed, maintained and replaced

We offer more sensory equipment and monitoring points on our systems than any other manufacturer

All models include self-cleaning probes

Our controls program provides:

Graphing

Trending

Charting

History

We provide built-in logic for oxygen control, nitrogen reduction and sludge management

STANDARD FEATURES

304 stainless steel reactor tankage

Membrane cassette(s)

Modular medium bubble diffusers

Powder coated controls panel

OPTIONAL FEATURES

Extended warranty

Buried installation with internal lift station, influent screen and flow meter

pH adjustment system

Denitrification

Package lift station

Prefabricated controls building

Sludge disposal equipment

Incorporation of existing controls equipment into Cloacina’s controls package

Energy saving controls package upgrades

Effluent flow metering

Additional equipment sound attenuation

Automated Clean In Place (CIP) system

Disinfection system

Thermal protection

Mobile units

Odor mitigation equipment

Automated foam control

Sediment/grit traps

Variety of grating and covers available

Project management

Equipment installation

Operations and maintenance training and services

Remote monitoring and support

IMAGES

VIDEOS

CLIENT INTERVIEWS

ANIMATIONS

ABOUT CLOACINA