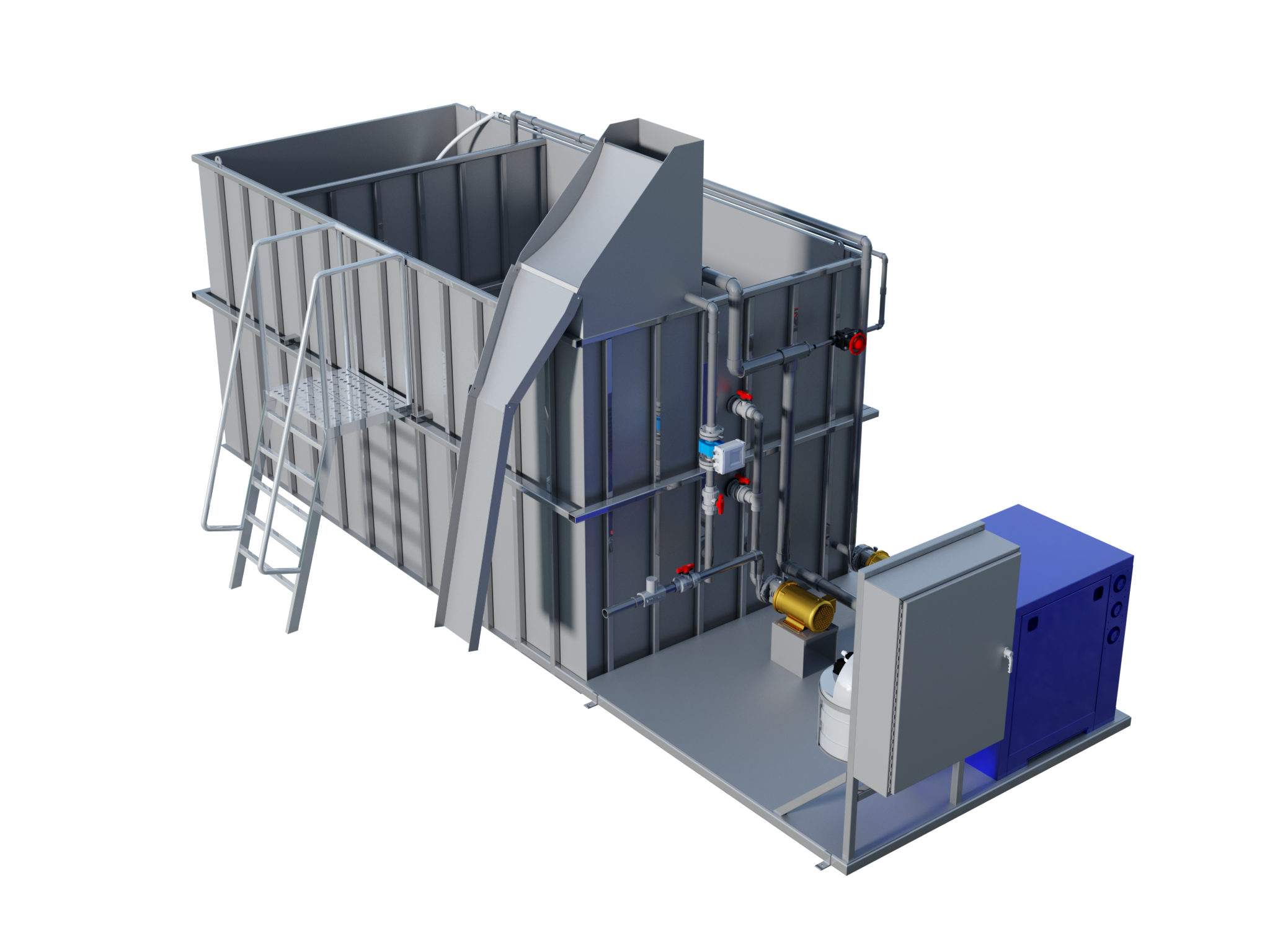

Cloacina’s Industrial Batch Reactor™ (IBR) is a package wastewater treatment plant that treats industrial wastewater utilizing activated sludge and clarification in a single vessel. All interior and exterior components are manufactured from high-quality, corrosion-resistant materials. The tank and equipment skid are fabricated from stainless steel. Cloacina’s IBR is ideal for clients needing a wastewater system with a small footprint that can pre-treat wastewater prior to sewer disposal, sub-surface reuse and frost and/or dust control water. The system includes a cutting-edge control system which allows facility staff to remotely access, monitor and make changes to the plant, collect data for reporting, view live on-site video and verify the completion of routine maintenance. The IBR is factory-tested, completely assembled prior to shipment and is easy to install, operate and maintain. Models are available for buried, partially-buried and above-grade installations. The Industrial Batch Reactor can be installed in compact and remote locations. Learn more here: https://www.cloacina.com/industrial-batch-reactor-ibr

MEMPAC-E for the Gold Creek Center in Sylmar, CA

Currently on the factory floor and under construction is a 10,000 gallon per day MEMPAC-E for the Gold Creek Center in Sylmar, CA. The MEMPAC-E is Cloacina's economy membrane bioreactor. Learn more here: https://www.cloacina.com/economy-membrane-bio-reactor

What to Expect in 2019

2019 is shaping up to be another historic year for Cloacina. See what to expect as the new year unfolds.

New Product: MEMPAC-H

The MEMPAC™-H is a hybrid equipment supply package designed for both municipal and industrial clients that need wastewater treatment equipment, but either already have or intend to supply their own tankage and piping. The MEMPAC-H is designed to accommodate extremely large projects and foreign clients that wish to minimize overseas shipping costs. This MEMPAC model uses Ultra Filtration (UF) membrane clarification and can either be a stand-alone unit or a complete Membrane Bioreactor (MBR) treatment system. These systems have expedited fabrication and delivery times and reduced on-site installation costs.

Learn more here: www.cloacina.com/hybrid-membrane-bioreactor

Mayacamus Factory Acceptance Testing

We recently completed construction on a 25,000 GPD MEMPAC-I for Mayacamas Warehousing in Sonoma, CA. Before it left the factory, it underwent rigorous Factory-Acceptance Testing (FAT) which included wet testing. Cloacina is one of the only manufacturers that fills all tanks to operating depth and then runs and tests the entire plant prior to shipping.

WINEXPO 2018

Come visit us at the WINEXPO in Santa Rosa on Thursday, December 6th at Booth 726

New Product: CEMPAC

Cloacina has revolutionized sludge thickening by being the first company to incorporate Silicon Carbide (SIC) membranes into a package sludge thickening system that can be easily installed at sites with thickening needs. Clients can now thicken sludge without the use of polymers and their downstream effects!

Cloacina Products are Manufactured in America!

Our products are manufactured in America! We are proud to provide local jobs and support the economy on the Central Coast!