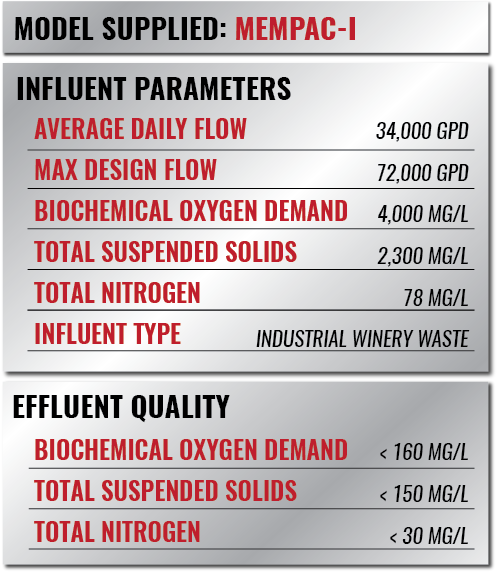

DESIGN PARAMETERS

The client, a winery crush facility, was seeking an efficient and sustainable way to manage process water with the goal of land applying the treated effluent. Traditional treatment options required a large land application area, which posed limitations for site planning and long-term operations.

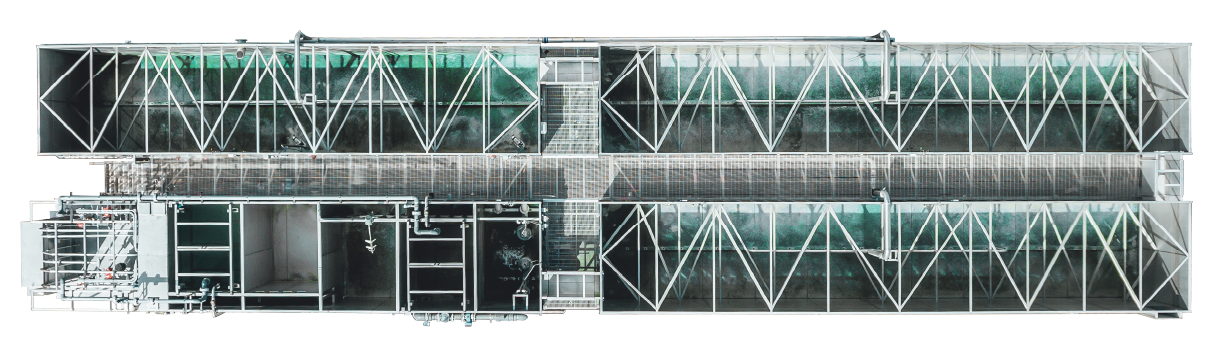

Cloacina provided a phased solution consisting of a roughing filter for primary treatment and a membrane bioreactor (MBR) system for advanced treatment. In Phase 1, the high-quality effluent produced by the MBR allowed the client to significantly reduce the land application area. The system was also designed for future expansion, enabling the winery to transition to reuse irrigation water in later phases—supporting both regulatory compliance and long-term water conservation goals.

CLOACINA SUPPLIED THE

FOLLOWING FOR THIS PROJECT:

-

Stainless steel process tanks

-

Redundant membrane air scour system

Clean-In-Place (CIP) system

-

Chemical dosing pumps

-

CompacLogix Allen Bradley control systems

Remote access, alarm, and data trending systems

SCADA integration

HMI (Human Machine Interface)

Flow meters, Level Sensors, ProcessInstrumentation

-

Submersible pumps (FAS)

Progressive cavity pumps (WAS/Sludge)

Bi-directional rotary lobe (Permeate)

-

Fine bubble diffusers

Blowers

-

Air compressor (for instrument cleaning)

Equipment/Electrical skids

Access platforms, stairs, and handrails

Internal piping and valves

Dewatering press

Lift station

-

1mm fine screen supplied as a stand-alone elevated platform.

Sludge storage

Effluent pumping

Effluent monitoring and off-spec diversion

Spare parts