TYPICAL APPLICATIONS

Reduces biosolids hauling volume prior to dewatering equipment, increases performance of on-site digestion equipment and decreases volume sent to holding ponds

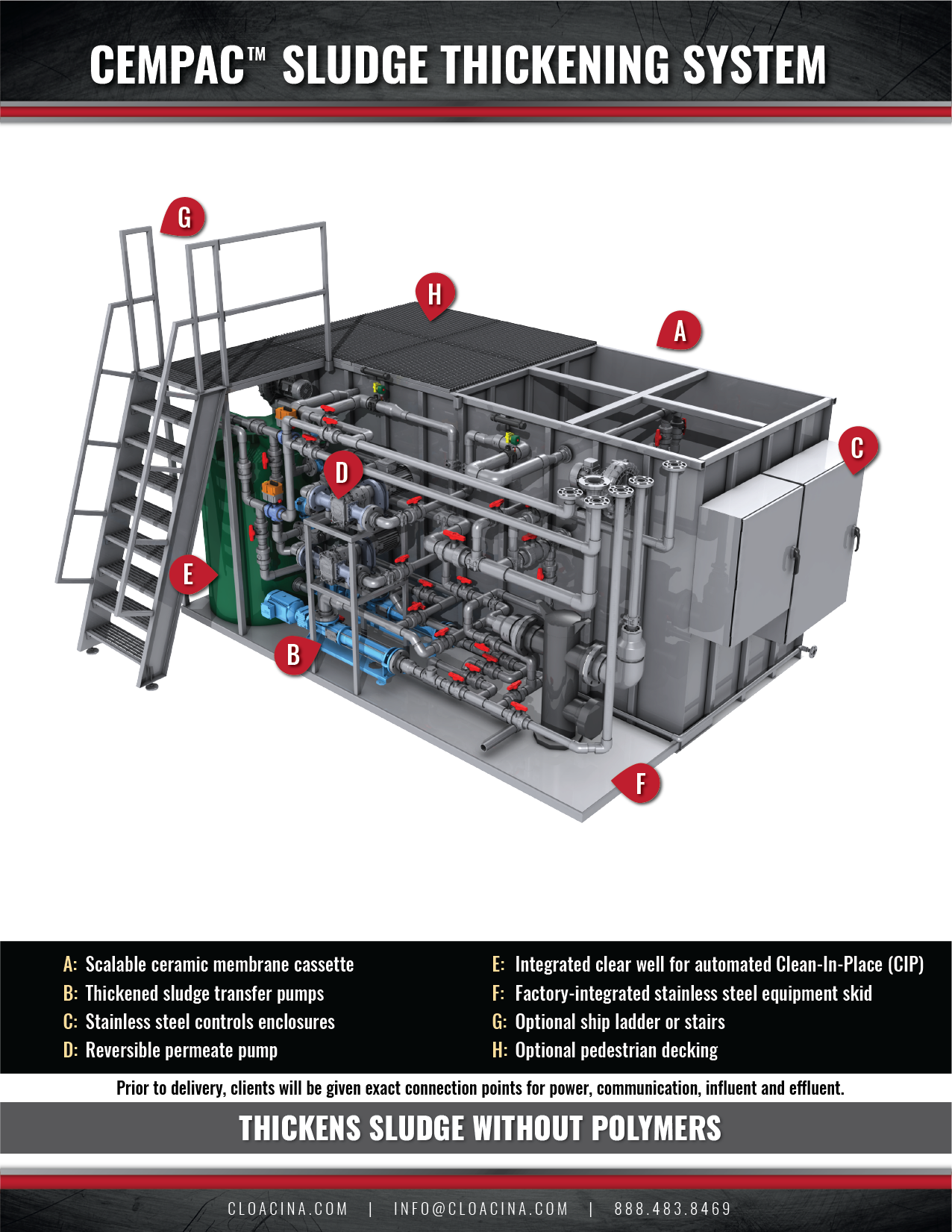

PRODUCT OVERVIEW

Cloacina has revolutionized sludge thickening by being the first company to incorporate Silicon Carbide (SIC) membranes into a package sludge thickening system that can be easily installed at sites with thickening needs. Clients can now thicken sludge without the use of polymers and their downstream effects! Cloacina’s CEMPAC includes a silicon carbide ceramic flat sheet membrane capable of thickening difficult waste streams: up to 5% solids, very high or low pH ranges and those containing abrasives. The membrane is extremely durable, can be pressure washed and, if properly cared for, has an expected useful life of decades. The membrane has easy recovery of flux and can be stored dry. The CEMPAC can be incorporated into any existing wastewater treatment system.

OPERATIONS AND MAINTENANCE-FRIENDLY FEATURES

Cloacina's package wastewater treatment plants are designed by operators for operators. Our Ownership Team has been building, installing, operating and maintaining water and wastewater systems for almost three decades. As a result, we know what operators and maintenance technicians need. Some of the revolutionary operations and maintenance-friendly features of our package wastewater treatment plants include:

Submerged sensory equipment is mounted on Cloacina’s Slide Rail System which provides mounting and support of equipment requiring precise installation and repeated removal for calibration and maintenance. This allows multiple pieces of equipment to be installed in tight spaces without tension on or tangling of power cords and controls cables.

The MEMPAC-M has built-in foam migration to keep foam and scum moving through the system and into a trap at the end of the treatment train

All process tankage on the MEMPAC-M has isolation gates for maintenance and emergency purposes

Equipment has pressure gauges or transducers for troubleshooting

All equipment has unions and/or flanged fittings for easy access and maintenance

All equipment is visible and easily accessed, maintained and replaced

We offer more sensory equipment and monitoring points on our systems than any other manufacturer

All models include self-cleaning probes

Our controls program provides:

Graphing

Trending

Charting

History

We provide built-in logic for oxygen control, nitrogen reduction and sludge management

STANDARD FEATURES

304 stainless steel

Ceramic membrane cassette

Flow and level monitoring

Cloacina controls package

Semi-sound attenuated blowers

Medium bubble diffusers

Cloacina’s Slide Rail System

Above-grade installation

OPTIONAL FEATURES

Upgraded controls package

316 stainless steel

Polymer addition

Buried or partially-buried installation

Hybrid model where the client provides the tankage

Sludge drying equipment

IMAGES

VIDEOS

PRODUCT SPOTLIGHT

ABOUT CLOACINA

CLIENT INTERVIEWS