Over the past decade, Cloacina has become a trusted resource for engineering firms across the United States. We specialize in providing a complete wastewater equipment menu from inlet to outlet. Our Engineering Team supports your design and Client from inception through start-up, installation and commissioning of the equipment and during the warranty period. Cloacina plants have expedited proposal, design, permitting, construction and installation time frames compared to traditional treatment methods. We provide process calculations, modeling, and documentation, per your specifications or ours, for selection and design of our plants and equipment including: equipment specifications, PFDs, P&IDs, controls panel drawings, controls strategies and equipment data for inclusion in your submittals.

You approve the design. We provide the process guarantee and equipment liability.

Working with Cloacina allows you to work on wastewater projects without a process engineer on staff and allows you to complete more projects every year acting as the Project Manager that oversees our pre-engineered designs. We can also assist your Client with the interface of our equipment with their existing facilities.

COMING SOON TO SOUTH CAROLINA

We are proud to announce that a 42,000 gallon per day MEMPAC-X is coming soon to a campground and RV park in North Carolina. Cloacina's MEMPAC-X is a cost-effective treatment solution designed for low flow domestic applications with stringent discharge requirements. The MEMPAC-X can treat 5,000 gallons per day with the standard Cloacina-supplied stainless steel tankage but is designed to be easily expanded to treat up to 25,000 gallons per day with the incorporation of additional Cloacina or client-provided external tanks. This system can reclaim 100% of the treated effluent for irrigation and sanitation purposes and has expedited construction and delivery timelines. Stay tuned for more details and photos from this project.

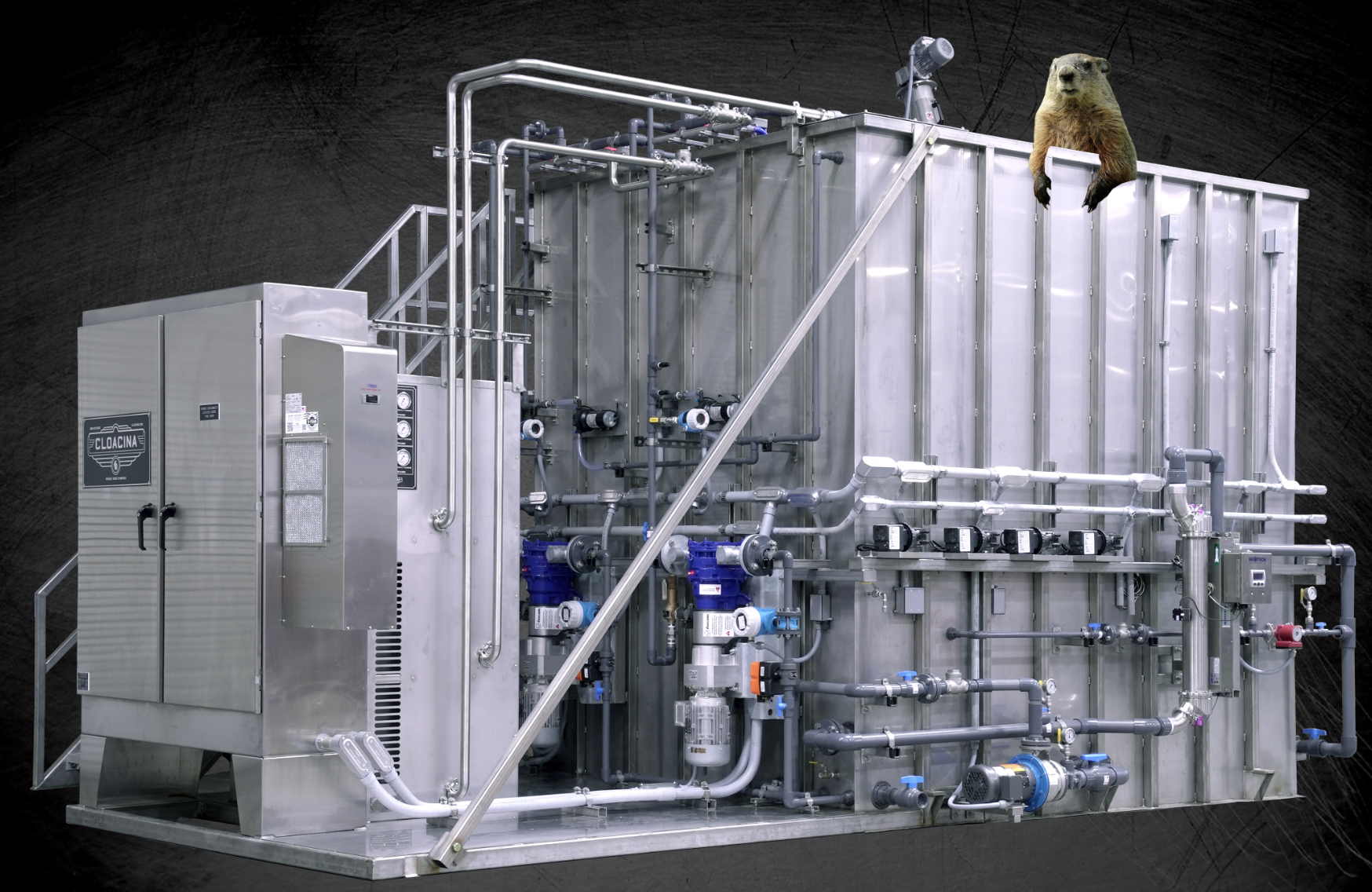

MEET THE MEMPAC-E (ECONOMY)

The MEMPAC-E membrane bioreactor is the perfect package wastewater treatment system for municipal clients who need an immediate treatment solution, those who are budget-conscious but still have to meet stringent discharge requirements or those with the desire to reclaim treated effluent for re-use. Designed for low flow ranges, the MEMPAC-E has standard, streamlined designs and economized equipment selections while still incorporating many of the same features that clients have become accustomed to on other MEMPAC models: All interior and exterior components are manufactured from high-quality, corrosion-resistant materials and all tankage and equipment skids are fabricated from stainless steel. Prior to shipment, all equipment is factory-installed and wet tested. The compact design of the MEMPAC-E makes it ideal for projects with small footprints and remote locations.

FACTORY ACCEPTANCE TESTING

ALL CLOACINA PACKAGE PLANTS AND EQUIPMENT UNDERGO RIGOROUS FACTORY ACCEPTANCE TESTING AS A COMPLETE SYSTEM PRIOR TO SHIPPING:

Tankage is cleaned and leak tested

All welds on the tankage are brushed and free of spatter and slag

All welds are cleaned and passivated through an electrochemical passivation process

Equipment is bump tested for functionality

Flow testing for pump rotation and leaks

All equipment is electrically tested and the results are recorded

Sensors are tested and calibrated

Membranes are tested

The controls system is tested in both manual and automatic modes

The controls system alarms, trending, notifications and setpoints are verified and recorded

All manual processes are performed and adjusted for easy operation

Equipment serial numbers are recorded

All factory setpoints are recorded

The system is cleaned and prepared for shipping

READY FOR 6 MORE WEEKS OF WINTER?

Do you need a package wastewater treatment system that can withstand six more weeks of winter?

Cloacina works with clients that need treatment options for extreme cold weather conditions. All Cloacina models include options for:

Insulation of hydraulic piping under 2”

Installation of tanks outside with the equipment skid in an enclosed building

Installation of the entire system indoors with sufficient clearance for operations and maintenance

COME SEE US AT UNIFIED

Stop by Cloacina’s booth at the Unified Wine and Grape Symposium in Sacramento from January 25th to January 27, 2022.

WHAT TO EXPECT FROM CLOACINA IN 2022

Happy New Year from everyone at Cloacina! Check out our latest video to see what to expect from us in 2022. This year we will be building package wastewater treatment plants capable of treating 1-2 million gallons per day, introducing our revolutionary new M-path design into our MEMPAC product line and installing plants across the country. Step right up to see the greatest membrane bioreactor on earth!

Happy Holidays!

May peace, happiness and prosperity be yours during this holiday season and throughout the New Year!

The Cloacina Family