DESIGN PARAMETERS

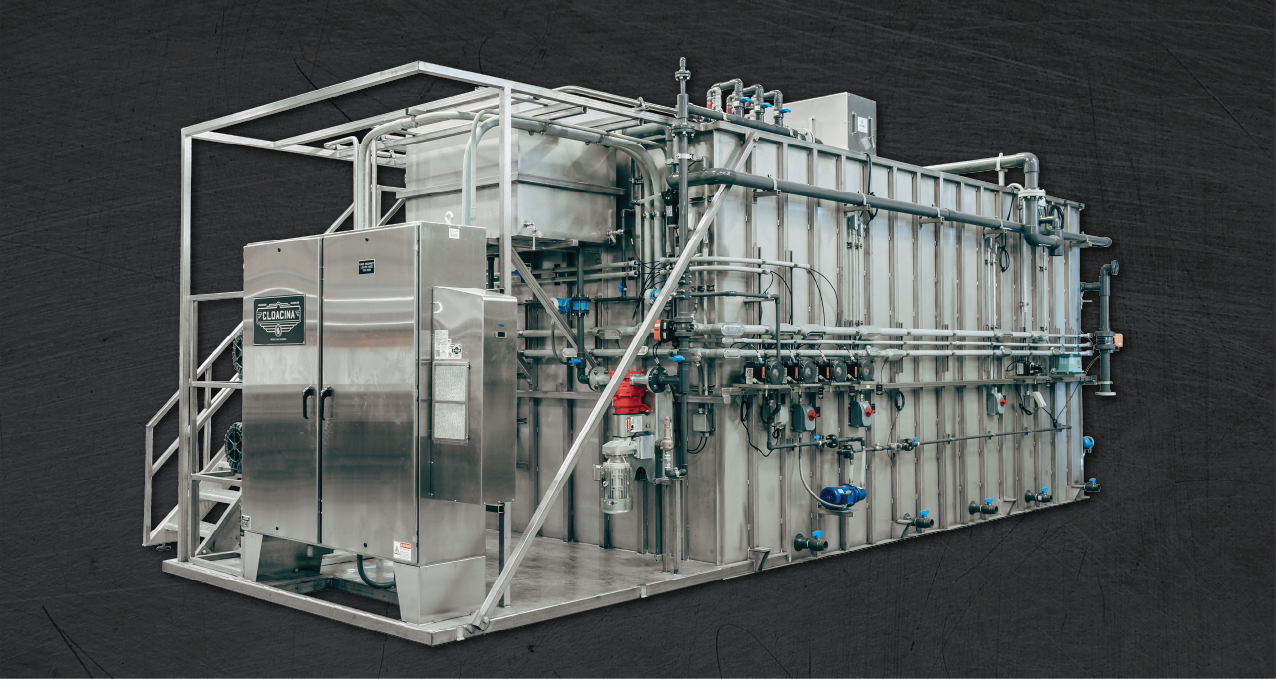

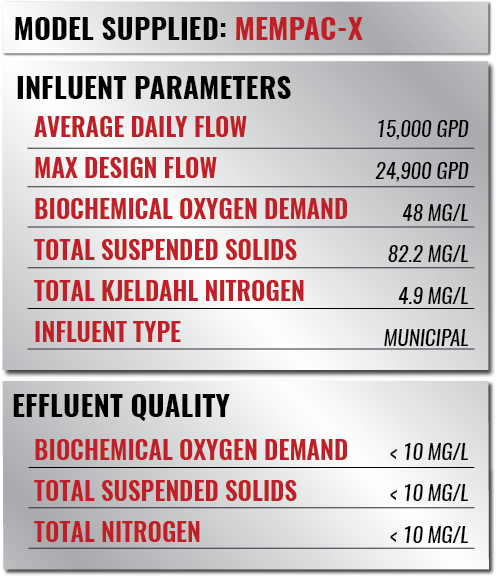

A state park in southern Arizona needed to replace an outdated wastewater treatment system that was no longer meeting effluent quality standards. Due to the site's proximity to a protected lake, the new system had to meet stricter discharge limits, including advanced nutrient removal and UV disinfection. Cloacina provided a MEMPAC-X packaged MBR system to deliver reliable, high-quality effluent in a compact footprint, minimizing impact on the surrounding environment and simplifying operations for park staff.

CLOACINA SUPPLIED THE

FOLLOWING FOR THIS PROJECT:

-

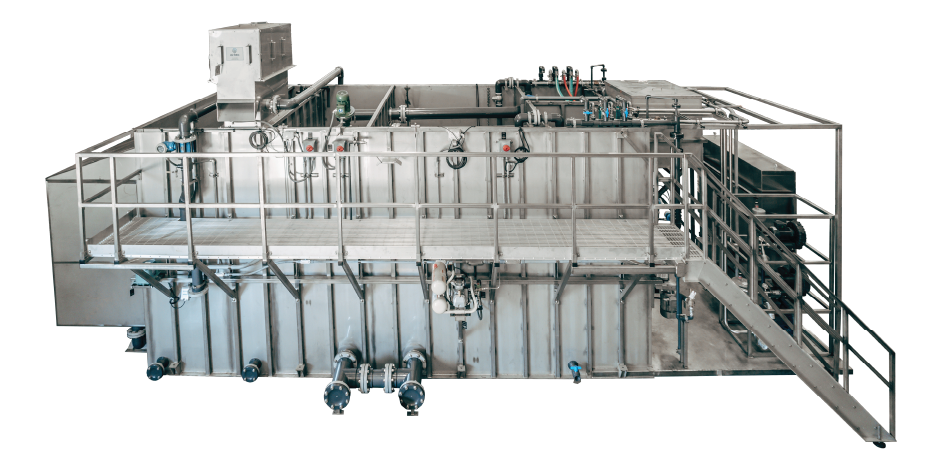

- Stainless steel process tanks

-

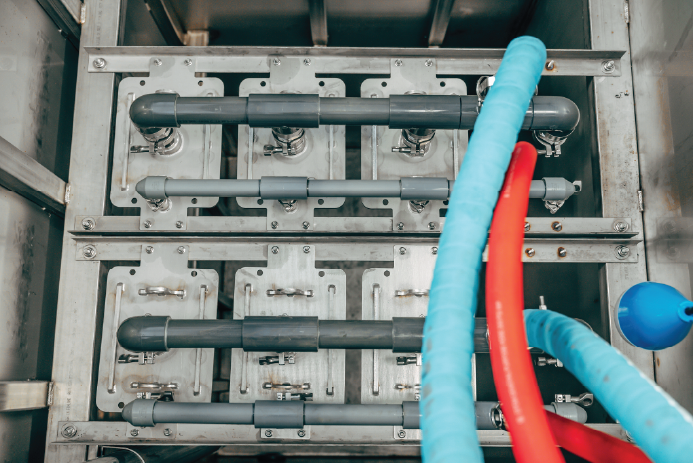

- Membrane air scour system

- Clean-In-Place (CIP) system

-

- Fine bubble diffusers

- Blowers

- Shaft Mixers

-

- CompacLogix Allen Bradley control systems

- Remote access, alarm, and data trending systems

- SCADA integration

- HMI (Human Machine Interface)

- Flow meters, level sensors, process instrumentation

-

- Submersible pumps (FAS)

- Progressive cavity pumps (WAS/Sludge)

- Bi-directional rotary lobe (Permeate)

-

- Air compressor (for instrumentation cleaning)

- HVAC systems (for panel enclosures)

- Equipment/electrical skids

- Access platforms, stairs, and handrails

- Internal piping and valves

-

- Chemical dosing pumps

-

- Rotary brush-style screens

-

- UV disinfection